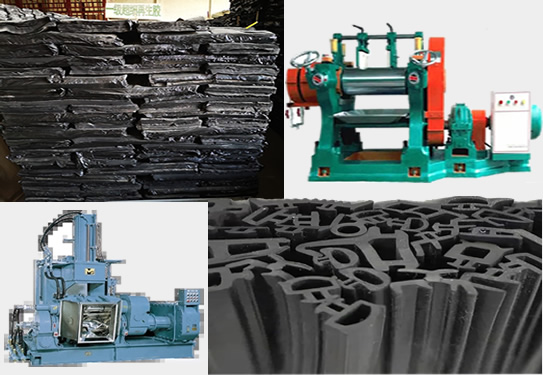

Rubber sealing strips are widely used in various transportation vehicles, building doors and windows, household appliances, industrial machinery, and other fields, playing a sealing role in preventing external dust, air, water, etc. from entering the internal system. Traditional rubber sealing strips are generally processed from natural rubber, styrene butadiene rubber, butadiene rubber, ethylene propylene rubber, and nitrile rubber as raw materials. The tire tread recycled rubber product processed from waste tires has a low price and can be used in the production of rubber sealing strips, effectively reducing manufacturing costs while ensuring product quality

1. Performance requirements for rubber materials used in rubber sealing strips

According to the usage environment of rubber sealing strips, the following requirements are put forward for the rubber used in the sealing strips: the rubber must have good processing safety, low Mooney viscosity, no frost spraying or discoloration, and most sealing strips also need to have strong tensile performance, compression permanent deformation resistance, and cold resistance. The regenerated rubber from waste tire top powder is characterized by high effective rubber hydrocarbon content and good elasticity. It can be used alone or in combination with natural rubber and styrene butadiene rubber to produce rubber sealing strips, effectively reducing costs

It should be noted that when using tire recycled rubber as sealing strips for indoor, door and window glass, etc., it is recommended to use environmentally friendly recycled rubber to avoid harmful substances affecting human health

2. Key points of formula design for rubber sealing strips in the production of recycled tire rubber ESY5Y12

In order to design the formula of the reclaimed rubber sealing strip of tire, it is necessary to comprehensively consider the appearance, structural stability and extrusion process performance of the rubber sealing strip

(1) The appropriate use of supportive additives such as ointment, polymer wax, modified plastics, etc. in the formula of tire recycled rubber sealing strips can provide better appearance quality and structural dimensional stability to the rubber sealing strips due to their good stiffness and small deformation

(2) Fully consider the extrusion process performance of the rubber used in the tire reclaimed rubber sealing strip. The use of ointment, mineral oil, clay, stearic acid, etc. can increase the extrusion speed of semi-finished products and make them smooth. The use of ointment and magnesium carbonate can reduce the deformation of semi-finished products during parking. Through the combination of compounding agent, the plasticity of the rubber compound is appropriately improved, the fluidity of the rubber material is increased, the surface of the semi-finished product is smooth, the scorch of the reclaimed rubber is reduced, and the extrusion speed is improved.

3. Practical formula reference for rubber sealing strips produced from recycled tire rubber

100 parts natural rubber, 100 parts recycled tire rubber, 6.5 parts zinc oxide, 5 parts stearic acid, 1.2 parts antioxidant A, 5.3 parts paraffin, 60 parts carbon black N330, 120 parts light calcium, 33 parts magnesium carbonate, 27 parts white ointment, 0.45 parts accelerator D, 0.85 parts accelerator DM, and 4.2 parts sulfur; Total: 463.5 copies

In actual production, when producing rubber sealing strips using natural rubber, natural rubber/styrene butadiene rubber, natural rubber/cis-1,4-polybutadiene rubber as raw materials, rubber product manufacturers can add a certain proportion of tire recycled rubber and choose environmentally friendly ultra-fine tire recycled rubber that will not change color or migrate. This effectively reduces raw material costs while ensuring the performance and lifespan of the sealing strips, and avoids the production of rubber sealing strips Discoloration and migration occur during use

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits