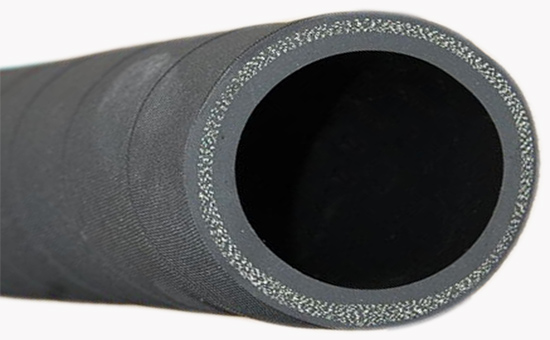

Ordinary hose wiping glue is cloth layer glue, which is used to firmly bond among the skeleton layers and among the skeleton layer and the inner and outer rubber layers. In actual production, wiping rubber requires good fluidity, permeability to fabric, adhesion, and certain strength and elongation performance and flexural fatigue resistance; generally natural rubber, styrene-butadiene rubber, butadiene rubber are used as The main raw materials are processed. The tire reclaimed rubber processed from waste tires can be added to the cloth wiping rubber to reduce the cost and adjust the formula appropriately, which can further improve the comprehensive index of the finished rubber hose.

1. Rubber raw materials

Ordinary hose wipers mostly use natural rubber as the main raw material, with appropriate amount of general-purpose rubber such as styrene-butadiene rubber, butadiene rubber, and neoprene rubber. When adding tire reclaimed rubber to the hose wiping rubber, the amount of reclaimed rubber should be reasonably controlled according to the technical index requirements of the cloth wiping rubber and the specific indicators of the tire reclaimed rubber 22LYY117, and the rubber content should be controlled among 35%-40%. Under normal circumstances, 30-100 parts of tire reclaimed rubber can be mixed with 100 raw rubber in the formula of ordinary cloth rubber hose, and the specific amount is determined according to actual needs.

2. Rubber accessories

When using tire reclaimed rubber to prepare low-cost ordinary hose wiping rubber, a sulfur-accelerated vulcanization system is generally used, and the vulcanization rate is slightly faster than that of the inner layer rubber; compared with raw rubber, the amount of sulfur and accelerator used in reclaimed rubber can be increased by up to 20%. It is recommended to use semi-reinforced carbon black, general-purpose carbon black, or a combination of the two for the reinforcing filling system; add inorganic fillers such as calcium carbonate and clay to control the dosage. It is recommended to use rubber softeners with good tackifying effects such as pine tar and heavy oil for ordinary hose rubbing.

In actual production, the dosage of compounding agents in the general rubber hose rubbing formula needs to be calculated according to the dosage of the original formula, the rubber content and the effective rubber hydrocarbon content of the tire reclaimed rubber.

3. Reference formula for ordinary hose wipes containing tire reclaimed rubber

80 parts of natural rubber, 20 parts of styrene-butadiene rubber, 115 parts of tire reclaimed rubber, 5 parts of zinc oxide, 0.5 parts of stearic acid, 2 parts of anti-aging agent, 30 parts of carbon black, 40 parts of clay, 15 parts of heavy oil, 12 parts of coumarone parts, 1.1 parts of rosin, 1.7 parts of accelerator, 3 parts of sulfur; total: 325.3 parts.

In actual production, the use of tire reclaimed rubber in the production formula of ordinary hose wiping rubber can not only reduce the cost of raw materials, but also improve the fluidity and plasticity of the rubber material, increase the extrusion speed, and reduce production energy consumption. Later, the editor will have the opportunity to continue to share with you the application skills of tire reclaimed rubber in ordinary wiping hoses, especially the mixing process and vulcanization process.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits