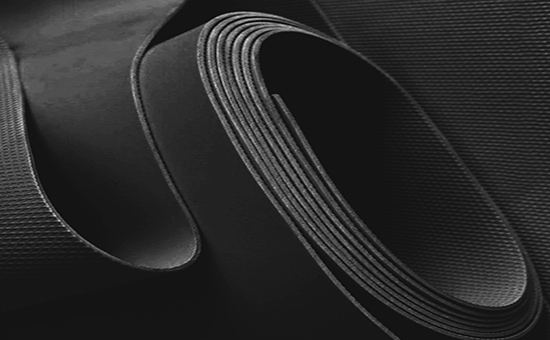

Tire rubber powder is a powdery substance prepared by physical methods such as normal temperature grinding and low temperature freezing and crushing of waste tires, which has the characteristics of good elasticity, wear resistance and aging resistance. Polyvinyl chloride is a polymer formed by the polymerization of vinyl chloride monomer in peroxides, azo compounds and other initiators or under the action of light and heat according to the free radical polymerization reaction mechanism, with good mechanical strength, good processing properties, dielectric properties and chemical stability. Tire rubber powder and polyvinyl chloride are blended to prepare thermoplastic elastomers with the dual characteristics of rubber and plastic, and are widely used in the rubber and plastic products industry.

1. Advantages of tire rubber powder blended with polyvinyl chloride to prepare thermoplastic elastomers

From the cost point of view, tire rubber powder is one of the ways to recycle waste tires, compared with traditional rubber materials, tire rubber powder has a low price, and PVC blending to prepare thermoplastic elastomers, which can reduce costs and improve product market competitiveness.

From the performance point of view, the thermoplastic elastomer after reasonable blending and modification of tire rubber powder and polyvinyl chloride inherits the high elasticity of rubber, which can produce large deformation without being destroyed when subjected to external force, and can quickly return to its original state after the external force is eliminated; The polyvinyl chloride material itself has good chemical corrosion resistance, etc., and after blending with rubber powder, it can maintain stable performance in high temperature, acid and alkali and other media, and prolong the service life.

The thermoplastic elastomer prepared by the blending of tire rubber powder and PVC has good processing performance, extrusion, injection, calendering and other molding methods, low processing energy consumption and high production efficiency, which can meet the manufacturing needs of products of different shapes and sizes.

2. Techniques for blending tire rubber powder with polyvinyl chloride to prepare thermoplastic elastomers

(1) Compatibilizer addition skills

When preparing thermoplastic elastomers by blending tire rubber powder and polyvinyl chloride, NBR nitrile rubber or CPE chlorinated polyethylene is mostly used as compatibilizers to improve the interface bond among the two and improve the tensile strength of thermoplastic elastomers. The NBR molecular chain contains double bonds, and the CPE is a saturated structure, so it is easier for NBR to form co-crosslinks with tire rubber powder, with high interfacial strength, and the compatibilization effect is slightly better than that of CPE. NBR is used in combination with CPE, and the capacitation effect in tire rubber powder/PVC blend is better.

(2) Plasticizer use skills

The processing properties of PVC materials can be improved by using plasticizers in moderation, and the commonly used plasticizer is DOP dioctyl phthalate. When DOP is not used, PVC is a brittle material, and the modulus difference among PVC and waste rubber powder is large; With the increase of DOP dosage, the modulus of PVC decreases and the brittleness is improved. It should be noted that the addition of DOP will lead to a decrease in the strength of PVC materials, so when waste tire rubber powder is blended with PVC, the amount of DOP needs to be reasonably controlled at 40-60 parts.

(3) Reaction processing time

When the tire rubber powder is blended with PVC to prepare the thermoplastic elastomer, the reaction processing time is appropriately increased, and the NBR and the waste tire rubber powder are gradually crosslinked, the interfacial strength is improved, and the thermoplastic elastic body mechanical properties are better. If the reaction processing time is too long, the degradation of PVC will occur during the high-temperature shearing process, and the mechanical properties of the material will be reduced. Therefore, it is necessary to reasonably control the reaction processing time, and if necessary, the amount of heat stabilizer can be appropriately increased.

(4) Particle size and dosage of waste tire rubber powder

When the waste tire rubber powder is blended with PVC material, it is recommended to choose 60-80 mesh tire rubber powder, the particle size of the rubber powder is too large, and the stress concentration of the blend material is more serious when it is stressed; With the increase of the amount of rubber powder, the mechanical properties of the blend material E5LYY218 a trend of first decreasing, then increasing, and then decreasing. When the dosage is too high, the interface compatibility becomes poor; The dosage of rubber powder is controlled at 40%-60%, and the thermoplastic elastic body mechanical performance of tire rubber powder blended with PVC is better.

The thermoplastic elastomer prepared by the blending of tire rubber powder and PVC has good mechanical strength, fluidity, thermal stability and chemical corrosion resistance, etc., and is widely used in automotive interiors, wire and cable sheaths, shoe soles, building sealing materials, and industrial parts.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits