The tire rubber powder made of waste tire rubber partially crushed has good elasticity, hardness, wear resistance and flexural resistance. The tire rubber powder is added to the matrix asphalt as a modifier, and the rubber powder modified asphalt can be made through high temperature, shearing and other processes, which has good high temperature stability, low temperature crack resistance, fluidity resistance, adhesion, etc., which can not only be used for road paving, but also can be used to prepare waterproof coatings, waterproof membranes, etc.

1. Application of tire rubber powder modified asphalt in waterproof coatings

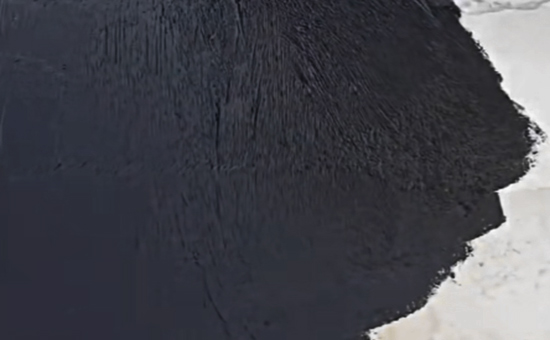

Tire rubber powder has good elasticity and adhesion, and adding it to asphalt can significantly improve the high-temperature stability and low-temperature crack resistance of asphalt. Add waste tire rubber powder to 160-170 °C hot asphalt, stir it evenly, and spray it on the surrounding walls of underground projects E4LYY1114 which can effectively improve the waterproof effect. Under normal circumstances, the use of 40-80 mesh tire rubber powder, the amount of rubber powder added is controlled at 20%-30% of the total amount of matrix asphalt, waterproof coating has a good waterproof effect and plastic deformation, low cost, good quality, convenient construction.

The lower the mesh number of rubber powder, the larger the particles, and the higher the elasticity and strength of the modified asphalt. The higher the mesh number, the more uniform the dispersion of the rubber powder and the better the construction fluidity.

Tire rubber powder modified asphalt production waterproof coating formula:

(1) 40 parts of petroleum asphalt, 20 parts of tire rubber powder, 40 parts of gasoline; Total 100 copies.

(2) 20 parts of petroleum asphalt, 15 parts of residual oil asphalt, 25 parts of tire rubber powder, 40 parts of gasoline; Total 100 copies.

(3) 35 parts of petroleum asphalt, 25 parts of rubber powder, 40 parts of gasoline; Total 100 copies.

2. Application of tire rubber powder modified asphalt in waterproofing membrane

Rubber powder modified asphalt can improve the elasticity and flexibility of the membrane, endow the waterproofing membrane with a better adaptation to the subtle deformation of the building structure, improve the problem that the traditional waterproofing membrane is prone to water leakage due to large temperature difference and structural deformation, and improve the overall waterproof performance of the building. Rubber powder modified asphalt has a certain absorption and reflection ability to ultraviolet rays, and the waterproofing membrane is not easy to age under strong sunlight, and the weather resistance is enhanced.

The production process and equipment of rubber powder modified asphalt waterproofing membrane are basically the same as those of SBS modified asphalt production waterproofing membrane, and the cost can be greatly reduced. In addition, the rubber powder modified asphalt waterproofing membrane can show excellent adhesion and ductility during the construction process, and can be paved by hot melt, cold bonding and other ways, which saves construction time and reduces construction complexity and labor intensity.

Tire rubber powder is one of the main ways to deal with waste tires, and rubber powder modified asphalt uses rubber powder made of waste tire rubber after fine processing for mixing and modification, which has higher elastic modulus, superior low-temperature crack resistance and good high-temperature stability; It can maintain good performance in a wide range of temperature changes, has good flexibility, and has a wide range of applications in waterproof coatings, waterproof membranes and other materials.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits