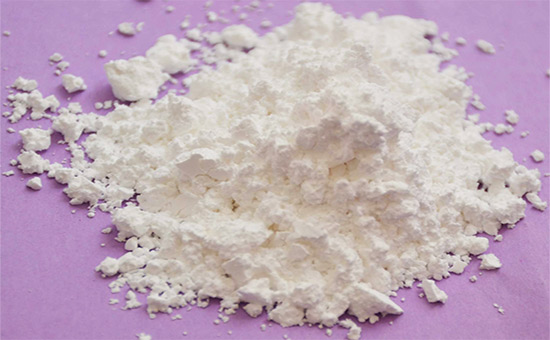

Calcium carbonate can increase product volume, reduce production cost (especially high-grade recycled rubber products), reduce rubber shrinkage, improve rubber rheology, etc. in the production of recycled rubber products; calcium carbonate used in rubber products industry has heavy carbonic acid Calcium, light calcium carbonate and limb calcium carbonate, the use of light calcium carbonate in the recycled rubber products industry. In the production process of recycled rubber products, it is beneficial to choose the right kind of calcium carbonate and reasonable control of the amount of calcium carbonate in quality and cost, but it is infinite after the wrong choice; then what should be paid attention to when selecting recycled calcium carbonate in the selection of calcium carbonate?

1. Pay attention to the content of harmful substances in calcium carbonate

Different types of calcium carbonate production methods are different. Heavy calcium is directly pulverized by mechanical methods such as calcite, limestone and shells; light calcium is calcined into lime after calcination, and then water is digested to produce lime milk, which is carbonized by carbon dioxide. Calcium carbonate is a treatment of light calcium or heavy calcium using a surface modifier. These calcium carbonates contain a certain amount of silicon, iron and harmful heavy metals. When selecting calcium carbonate for recycled rubber products, it is necessary to choose calcium carbonate with high content of silicon, iron compounds and low levels of harmful heavy metals.

2. Pay attention to calcium carbonate whiteness

Calcium carbonate is a typical white rubber filler, but the color of calcium carbonate processed from different raw materials is different. When using recycled rubber to produce rubber products, especially light-colored recycled rubber products, choose calcium carbonate with high whiteness as much as possible. The "face value" of recycled rubber products.

3. Pay attention to the calcium carbonate oil absorption value

The so-called oil absorption value, which is an index of the amount of rubber filler absorbed by the resin, is usually expressed as the mass of linseed oil required for 100 g of powder material, that is, the minimum amount of oil used when 100 g of the sample reaches complete wetting; The maximum amount of DBP that can be absorbed by 100g of calcium carbonate powder is the oil absorption value of the product. In the production process of recycled rubber products, the higher the oil absorption value of calcium carbonate, the easier it is to adsorb the plasticizer in the formulation into the rubber filler, thus losing the plasticizing effect. The reclaimed rubber needs to increase the amount of plasticizer to achieve a fixed softness. The production cost of recycled rubber products is too high, so the lower the oil absorption value of calcium carbonate used in the production of recycled rubber products, the better.

Generally, the surface of the calcium carbonate particles is coated or treated with a coupling agent to lower the oil absorption value of the calcium carbonate.

4. Pay attention to the fineness of calcium carbonate

Many manufacturers of recycled rubber products often fall into such a misunderstanding when choosing calcium carbonate: the higher the fineness of calcium carbonate, the more favorable it is for recycled rubber products; this is not the case. The effect of different fineness of calcium carbonate in reclaimed rubber is different. Recycled rubber products manufacturers need to determine according to the actual situation of reclaimed rubber demand and calcium carbonate particle size distribution.

5. Does calcium carbonate need to be activated?

Activated calcium carbonate is a calcium carbonate modified by a surface modifier. It has a certain reinforcing effect in the reclaimed rubber. It can replace some white carbon black in some special occasions and reduce the production cost. However, in actual production, not all calcium carbonate used in recycled rubber products needs to be surface-activated. Whether activation is determined according to actual conditions.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits