Speaking of calcium carbonate, this is one of the most commonly used rubber fillers in the rubber products industry. According to the production methods, it can be divided in heavy calcium carbonate, light calcium carbonate, calcium carbonate as well as crystalline calcium carbonate. The first three types can be used in rubber. In the production of products. The greatest effect of using calcium carbonate in rubber products is to increase the volume of rubber products and reduce the amount of rubber in order to reduce the production cost of rubber products; in actual production, calcium carbonate can not only reduce the amount of rubber and improve the part of rubber products in rubber products. Indicators also affect the color of rubber products.

1. The effect of light calcium carbonate on the color of rubber products

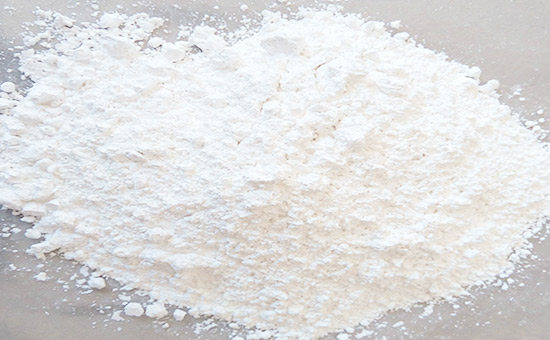

Lightweight calcium carbonate is a non-toxic, odorless, non-irritating odor of white powder. It is the largest amount of calcium carbonate in the rubber industry. A large amount of light calcium in the rubber can increase the solvent of rubber products and reduce the amount of high-priced rubber raw materials. Rubber products tensile strength, tear strength, reinforcing properties and adjust the viscosity of rubber. Calcium carbonate is a typical white filler. Filling a large amount of white rubber products can increase the whiteness of the rubber products. However, if a large amount of calcium carbonate is added to the black rubber products, the resulting black rubber products will have a gray surface and a low gloss. Therefore, black rubber products must be used with caution.

2. The effect of calcium carbonate on the color of rubber products

The calcium carbonate of the limb is activated calcium carbonate, modified calcium carbonate, and activated calcium carbonate, and is a calcium carbonate prepared by modifying the surface of light calcium or heavy calcium with a surface modifier, and has better reinforcing performance. Active calcium carbonate is a kind of white and delicate light powder. It has better reinforcing and dispersibility in rubber products than light calcium or heavy calcium. It can improve the elongation, tensile strength and wear resistance of rubber products. Improve the surface gloss of rubber products, especially the production of white, light-colored rubber products, the surface color brilliant, smooth appearance.

Calcium carbonate can be used not only in the production of rubber products, but also in the production of reclaimed rubber products. Taking white latex reclaimed rubber as an example, many rubber product manufacturers may have such a question: Why do some reclaimed rubber factories produce plastic containing rubber? Low-cost, low-cost latex reclaimed rubber has better whiteness? In fact, this is well understood, that is, low-priced white latex reclaimed rubber will be filled with white light calcium in the production process; high latex content of latex reclaimed rubber is required to adjust the whiteness of reclaimed rubber by titanium dioxide and other compounding agents, different reclaimed rubber The amount of compounding agent in the factory is different, so the white latex reclaimed adhesive produced has a different degree of whiteness, but Xiao Bian wants to interpolation: High-content white latex reclaimed rubber is not as good as low-priced white latex reclaimed rubber. ” does not mean that the product quality is not good.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits