Regenerative glue swelling agent is a softener, mainly in the production and processing of reclaimed rubber swelling, viscosifying, plasticizing effect: It can increase the distance between the molecular chains and reduce the force between the molecular chains, and then help Living chemicals or other chemicals in the network structure of rubber molecules to promote the fracture of cross-linked bonds; while the swelling agent in the high-boiling substances in the regeneration of high temperature can remain in the rubber compound to increase the viscosity and plasticity of recycled rubber.

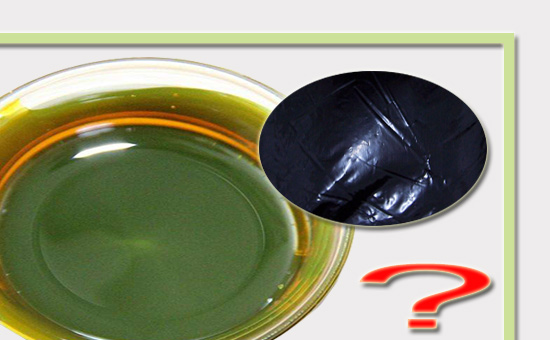

There are many kinds of regenerated plastic swelling agents, aromatic oil, naphthenic oil, heavy oil and paraffin oil in petroleum swelling agent, coal tar solid coal tar, biomass tar agent, Rosin, wood tar, etc .; in addition there is a small amount of solid swelling agent. Different types of swelling agent product performance is different, so when choosing swelling agent, should follow the following principles:

Improve the tensile elongation at reclaimed rubber To choose to contain unsaturated double bonds, high activity of swelling agent to improve the tensile strength of reclaimed rubber to choose a ring structure, a larger molecular weight swelling agent; want to improve and reclaimed rubber Rubber compatibility, the best choice contains more polar groups swelling agent.

Different swelling agent products are used for different purposes, such as aromatic oil used for tire reclaimed rubber, rubber reclaimed rubber, rubber and other dark reclaimed rubber products production; naphthenic oil, paraffin oil can be used for the production of environmentally friendly rubber products ; Mechanical oil is used for the regeneration of waste tire rubber powder; coal tar (solid, liquid) is used in the production of low-grade reclaimed rubber but it has been banned by the state; pine tar helps to disperse and increase the viscosity of the compounding agent Sex, improve product cold resistance, is a general-purpose plasticizer, but not suitable for light-colored recycled plastic products.

Other biomass swelling agents are mostly used in the production of environmentally-friendly recycled rubber and products, but their effects are also different: the rosin oil contains organic acid groups, which can improve the rubber compound adhesion, promote the dispersion of the compounding agent and delay the vulcanization speed; Limonene can improve the Mooney viscosity of reclaimed rubber to improve the elongation at break of the reclaimed rubber and significantly improve the regeneration effect. Wood tar can also improve the physical processing properties of reclaimed rubber, and can also improve the adhesive properties, low temperature resistance and scorch prevention of rubber compounds , But its softening ability is poor; added tall oil reclaimed rubber products processing non-stick roller, the pollution is low.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits