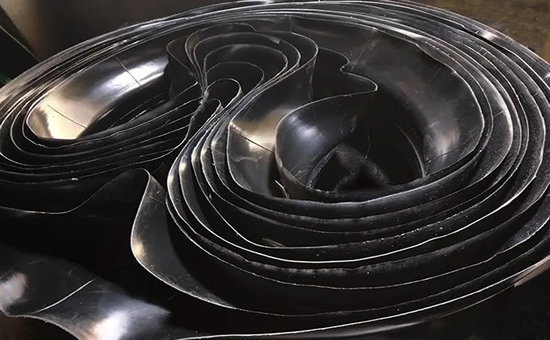

The rubber cushion belt, namely the lining belt and strip, is thick in the middle and thin at the edge. The rubber material is required to have good bending flexibility, tear resistance and aging resistance, and the requirements for physical and mechanical properties are not high. In actual production, the tire cushion belt is generally processed with natural rubber, styrene butadiene rubber and CIS polybutadiene rubber as the main raw materials; The following three kinds of reclaimed rubber are ideal raw materials to replace high priced raw rubber, which can be used in the production of tire cushion belt and effectively reduce the cost of raw materials.

1. Mix latex reclaimed rubber to produce cushion belt

Latex reclaimed rubber, also known as natural reclaimed rubber and natural latex reclaimed rubber, is mainly used to replace natural rubber. Latex reclaimed rubber has high effective rubber hydrocarbon content, high tensile strength, high elongation at break and good elasticity. It has the basic properties of natural rubber. It can directly replace some natural rubber to produce tire cushion belt and reduce the cost of raw materials. The price of black natural reclaimed rubber with the same physical and mechanical strength is lower than that of white latex reclaimed rubber. It is recommended to use hy2yy14ee black latex reclaimed rubber for rubber cushion belt to reduce more costs.

2. The cushion belt is mixed with tire recycled rubber

Tire reclaimed rubber is the reclaimed rubber with the largest output and the most application in the reclaimed rubber market at present. It has good compatibility with general rubber such as natural rubber, styrene butadiene rubber and CIS butadiene rubber. It can be mixed in the formula of tire cushion belt to reduce raw material cost and power consumption. In actual production, it is suggested to use fine particle tread reclaimed rubber for tire cushion belt, which can better ensure the mechanical properties of the finished cushion belt while reducing the cost.

When using natural rubber / styrene butadiene rubber / tire reclaimed rubber and rubber to produce tire cushion belt, an appropriate amount of CIS butadiene rubber can also be added to improve the flexion resistance and flexibility of the rubber. Generally, when the amount of raw rubber (total amount of natural rubber, styrene butadiene rubber or CIS polybutadiene rubber) is 100 parts, more than 200 parts of tire recycled rubber can be added.

3. A small amount of cushion belt mixed with butyl reclaimed rubber

The butyl reclaimed rubber processed from waste butyl inner tube has the characteristics of good air tightness, heat resistance and chemical corrosion resistance. It is mainly used to replace butyl rubber or chlorinated butyl rubber, and can also be used to improve the aging resistance of EPDM. When using natural rubber / styrene butadiene rubber / tire reclaimed rubber as raw material to produce tire cushion belt, 5-10 parts of butyl reclaimed rubber can be added to improve the overall flexion cracking resistance, tear resistance and heat resistance of the rubber.

In actual production, the addition of reclaimed rubber can not only reduce the cost, but also improve the plasticity, fluidity and anti vulcanization antigenicity of the compound. The tire cushion belt containing reclaimed rubber is generally vulcanized with sulfur accelerator system, reinforced with carbon black, filled with calcium carbonate and softened with aromatic hydrocarbon oil. It is suggested that the two kinds of anti-aging agents be used together to further improve the aging resistance. In the production of tire cushion belt, not only latex reclaimed rubber, tire reclaimed rubber and butyl reclaimed rubber can be used, but also an appropriate amount of tire rubber powder can be added. In the later stage, Xiaobian will continue to discuss relevant issues with you.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits