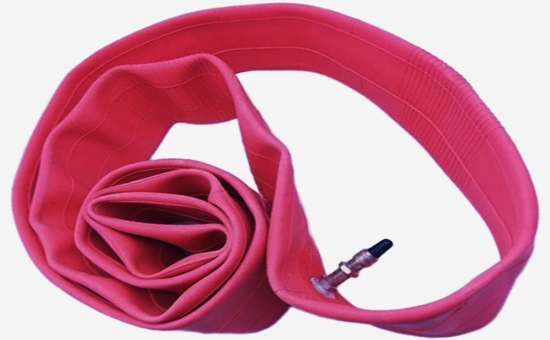

Red bicycle inner tubes produced primarily from natural rubber as the main raw material have good elasticity and puncture resistance. White latex reclaimed rubber is made from waste natural rubber, waste latex, and their products (such as waste rubber cups, waste latex gloves, etc.) through processes including crushing, desulfurization, sterilization, drying, and filtering. It possesses the basic performance characteristics of natural rubber: good elasticity, high strength, light color, low density, and no odor. It can replace natural rubber in the production of red bicycle inner tubes, thereby reducing raw material costs.

1. Key Points in the Formulation Design of Red Bicycle Inner Tubes Using White Latex Reclaimed Rubber

White latex reclaimed rubber has good compatibility with natural rubber and can be used alone or in combination with natural rubber to produce red rickshaw inner tubes, reducing raw material costs. If necessary, it can also be used with a small amount of butyl rubber to further improve the air tightness of the rickshaw inner tubes.

When producing inner tubes using a combination of latex reclaimed rubber and natural rubber/latex reclaimed rubber, a sulfur-accelerator system is often used. For example, using accelerators M and CZ together can shorten the vulcanization time and lower the vulcanization temperature. Choosing lightweight calcium carbonate E5LYY519 as a filler can reduce costs and, to some extent, improve the inner tube compound's wear resistance, tensile strength, and tear resistance. Red inner tubes are often colored with rubber red or iron oxide red.

2. Reference Formula for Producing Red Bicycle Inner Tubes with Recycled White Emulsion Adhesive

(1) Reference formula for producing red bicycle inner tubes using a combination of natural rubber/latex and reclaimed rubber

Natural rubber 70 parts, white latex reclaimed rubber 30 parts, zinc oxide 5 parts, stearic acid 2 parts, antioxidant A 1 part, wax 1 part, light calcium carbonate 60 parts, barium sulfate 5 parts, rubber red 0.5 parts, RX-80 resin 1 part, machine oil 1.5 parts, accelerator DM 0.5 parts, accelerator D 0.1 parts, accelerator CZ 0.3 parts, sulfur 2.4 parts; total 180.3 parts.

Natural rubber 60 parts, white latex reclaimed rubber 40 parts, zinc oxide 5 parts, stearic acid 1.5 parts, antioxidant A 1 part, wax 1 part, light calcium carbonate 50 parts, lithopone 8 parts, iron oxide red 4 parts, diarylamine yellow 0.15 parts, orange yellow 0.1 parts, petroleum jelly 1 part, accelerator M 0.6 parts, accelerator DM 0.7 parts, accelerator D 0.05 parts, sulfur 2.2 parts; total 175.3 parts.

(2) Reference formula for producing red bicycle inner tubes using a combination of full latex and reclaimed rubber

White latex reclaimed rubber 100 parts, zinc oxide 5 parts, stearic acid 1.5 parts, antioxidant A 1 part, antioxidant D 0.5 parts, paraffin 1 part, light calcium carbonate 50 parts, lithopone 8 parts, rubber red 0.7 parts, Vaseline 1 part, accelerator M 0.5 parts, accelerator DM 0.3 parts, accelerator CZ 0.3 parts, salicylic acid 0.2 parts, sulfur 2.3 parts; total 172.3 parts.

White latex reclaimed rubber 100 parts, zinc oxide 5 parts, stearic acid 2 parts, antioxidant A 0.5 parts, antioxidant D 1 part, light calcium carbonate 45 parts, red iron oxide 1.5 parts, Vaseline 1 part, lithopone 10 parts, accelerator M 0.5 parts, accelerator DM 0.3 parts, accelerator CZ 0.3 parts, sulfur 2.3 parts; total 169.4 parts.

When selecting white latex reclaimed rubber for bicycle inner tubes, it is recommended to choose reclaimed rubber products with high fineness and no impurities, as this will provide better air tightness for the finished inner tube. Later, we will share with you the key points of mixing and vulcanization processes for producing red bicycle inner tubes using latex reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits