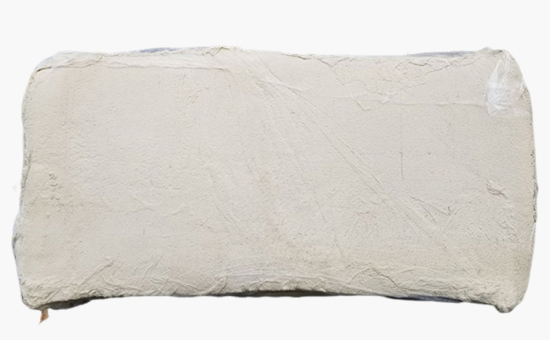

White latex reclaimed rubber is processed from waste natural rubber, waste latex and its products as raw materials, with good elasticity, high strength, small specific gravity, light color, easy color matching, etc., is an ideal raw material for replacing natural rubber to produce colored rubber products. When using white natural reclaimed rubber to produce white and colored rubber products (such as rubber soles, children's tires, and colored rubber sheets), you must choose the right colorant and use the right colorant.

In the production of rubber products, the substances added to the rubber compound for the purpose of changing the color of the product are colorants, which can be divided into two categories: inorganic colorants and organic colorants. Inorganic colorants are inorganic pigments, with good heat resistance, light resistance, strong hiding power, excellent solvent resistance, chemical resistance and migration resistance, but poor tinting strength; Organic colorants include organic pigments and some dyes have the advantages of many varieties, good dispersion, bright color, strong tinting strength, good transparency, and low dosage, but poor heat resistance, solvent resistance, chemical resistance, and migration resistance.

1. Varieties and characteristics of inorganic colorants commonly used in white natural latex reclaimed rubber products

(1) Titanium dioxide (titanium dioxide): odorless and tasteless white powder, which is the strongest variety of white pigments, with excellent hiding power and colorfastness. The price of titanium dioxide is high, and white latex reclaimed rubber E4LYY1115 used in combination with other white colors when producing white rubber products; It should be noted that the smaller the content of titanium dioxide in the mixed pigment, the lower the tinting strength.

(2) Zinc barium white (lithopone): a mixture of zinc sulfide and barium sulfate, white powder. The hiding power and tinting power of lithopone powder are greater than that of zinc white, but not as good as titanium dioxide, the price is low, and the product has yellowing phenomenon after exposure; It has poor dispersion in rubber and is easy to agglomerate, so it should be fully mixed when used; It can be used as a filler, and has a certain reinforcing effect on white latex reclaimed rubber.

(3) Color pigments: cadmium red (selenium red), iron oxide red (iron dan, iron red), chromium yellow (lead chrome yellow), zinc yellow (zinc chromium yellow), chromium trioxide, ultramarine, etc. are inorganic colorants, which can be used for the coloring formula of white latex reclaimed rubber products of corresponding colors.

2. Varieties and characteristics of commonly used organic colorants for white natural latex reclaimed rubber products

(1) Red series: toluidine red, lisol red, para-red, bright red, permanent red 2B, pyrazolinone red, sulfur red, quinidone red, naphtholol red, lisol red, dian red C, lisol red, etc.

(2) Yellow pigments: lightfast yellow, benzidine yellow, sand yellow, etc.

(3) Blue pigments: phthalocyanine blue, peacock blue, yin danslin blue, etc.

(4) Black pigments: aniline black, etc.

(5) Green pigments: phthalocyanine green, etc.

(6) Purple pigments: methyl violet, benzyl violet, etc.

When using latex reclaimed rubber to produce colored rubber products, the tinting strength of organic pigments is greater than that of inorganic pigments, and the technical requirements of specific rubber products can be met by selecting suitable pigments or mixed pigments. Most organic pigments have different properties in terms of heat resistance, light resistance, solvent resistance, etc.; The migration resistance and vulcanization resistance of organic pigments are different, and some pigments will react with sulfur during the vulcanization process to cause discoloration, so they are not suitable for use.

When using white latex reclaimed rubber to produce white and colored rubber products, the uniformity and consistency of color is an important indicator of quality control. The use of colorants can ensure that the color of rubber products meets the standard requirements, which is convenient for quality inspection and control in the production process; Rubber products manufacturers must choose the right color colorant according to the actual needs, reasonably control the amount of colorant, and improve the yield and production efficiency of color latex reclaimed rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits