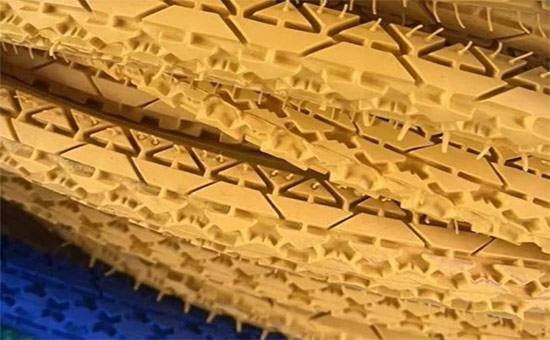

Bicycle tires mainly include tread, sidewall, carcass and other structures, tread rubber requires rubber to have good wear resistance, elasticity, tear resistance, etc., generally processed with natural rubber as the main raw material, and the appropriate amount of reclaimed rubber can effectively reduce the cost of raw materials. Latex reclaimed rubber is processed from waste natural rubber, waste latex and its products as raw materials, which has the performance characteristics of high mechanical strength, good elasticity, wear resistance, tear resistance, etc., which can replace natural rubber to produce bicycle tires, reduce costs and improve the performance of rubber processing technology.

1. The application method of latex reclaimed rubber bicycle tire tread rubber

There are three main ways to apply latex reclaimed rubber in bicycle tire tread rubber: (1) latex reclaimed rubber and natural rubber, styrene-butadiene rubber, butadiene rubber and other general rubber are used in an appropriate proportion to produce bicycle tires; (2) Completely use latex reclaimed rubber to produce bicycle tires; (3) Latex reclaimed rubber is used together with other reclaimed rubber, such as tire reclaimed rubber and isoprene reclaimed rubber, to produce bicycle tires to further reduce the cost of raw materials.

2. Latex reclaimed rubber produces vulcanized formula for bicycle tire tread rubber

(1) Natural rubber/latex reclaimed rubber and vulcanization formula for the production of bicycle tread rubber

50 parts of natural rubber, 50 parts of latex reclaimed rubber, 5 parts of zinc oxide, 1.5 parts of stearic acid, 1 part of paraffin, 0.3 parts of antioxidant A, 0.7 parts of antioxidant D, 15 parts of carbon black N330, 22 parts of carbon black N774, 15 parts of light calcium carbonate, 1.1 parts of accelerator M, 0.15 parts of accelerator TMTD, 1.95 parts of sulfur; Total 163.7 copies.

(2) Natural rubber/butadiene rubber/latex reclaimed rubber is used to produce a vulcanization formula for bicycle tread rubber

35 parts of natural rubber, 15 parts of butadiene rubber, 50 parts of latex reclaimed rubber, 0.5 parts of paraffin, 0.5 parts of antioxidant D, 0.2 parts of antioxidant H, 17 parts of carbon black N220, 10 parts of carbon black N660, 3 parts of light calcium carbonate, 1.1 parts of petroleum jelly, 0.25 parts of accelerator M, 0.25 parts of accelerator DM, 0.6 parts of accelerator CZ, 1.3 parts of sulfur; Total 134.7 copies.

(3) Completely use latex reclaimed rubber to produce bicycle tread rubber vulcanization formula

100 parts of latex reclaimed rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 1 part of paraffin, 0.5 parts of antioxidant A, 0.5 parts of antioxidant D, 35 parts of carbon black N330, 15 parts of carbon black N774, 20 parts of light calcium carbonate, 9 parts of coal tar, 0.85 parts of accelerator M, 0.15 parts of accelerator D, 2 parts of sulfur; Total 191 copies.

(4) Latex reclaimed rubber/tire reclaimed rubber is used to produce a vulcanization formula for bicycle tread rubber

75 parts of latex reclaimed rubber, 25 parts of tire reclaimed rubber, 4 parts of zinc oxide, 2.4 parts of stearic acid, 0.3 parts of paraffin, 0.6 parts of antioxidant A, 0.3 parts of antioxidant D, 15 parts of carbon black N330, 12 parts of carbon black N774, 12 parts of light calcium carbonate, 2 parts of pine tar, 1.1 parts of accelerator M, 0.1 parts of accelerator TMTD, 1.7 parts of sulfur; Total 151.5 copies.

3. Bicycle tire tread rubber with latex reclaimed rubber selection skills

When using latex reclaimed rubber to reduce the production cost of bicycle tire tread rubber, it is necessary to select the appropriate latex reclaimed rubber according to the color and physical and mechanical properties of the tire. For example, the black bicycle tire tread rubber can be E4LYY115 with black latex reclaimed rubber, which is more cost-effective; The color tire tread can use white latex reclaimed rubber, which is easy to match and not easy to change color. Reasonably determine the proportion of latex reclaimed rubber to better ensure the good wear resistance, safety, puncture resistance, tear resistance and so on of bicycle tire tread rubber.

In actual production, latex reclaimed rubber can not only be used to prepare bicycle tire tread rubber, but also tire sidewall, carcass, bead and inner tube can use an appropriate amount of latex reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits