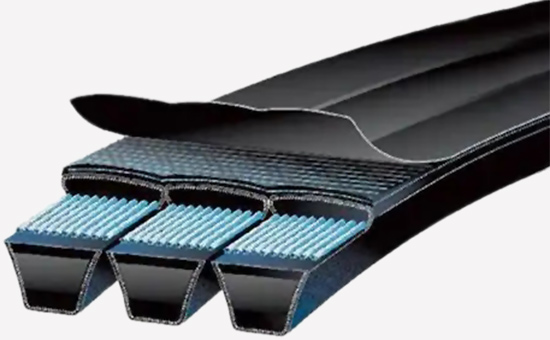

Rubber V-belts are mainly used in machinery and equipment for transmitting force and transporting goods, and are widely used in the automotive industry, industry, and agriculture. Ordinary rubber V-belt rubber mainly includes cloth layer rubber, stretch layer rubber, cord layer rubber, compression layer rubber, etc., the cloth layer rubber is generally processed from natural rubber, styrene-butadiene rubber or neoprene rubber, and the appropriate amount of black natural latex reclaimed rubber can not only reduce the cost of raw materials, but also improve the processing technology performance of rubber compounds.

1. Rubber V-belt wrapping layer rubber performance requirements

The function of the rubber V-belt wrapping is to connect the parts into a whole and protect the other parts from wear and tear. Generally, the rubber coating layer requires the rubber material to have certain adhesion and wear resistance, heat resistance, aging resistance and flexural resistance, and has good adhesion performance with the cloth layer, etc., generally using natural rubber, neoprene rubber or styrene-butadiene rubber, and the glue content is controlled at about 50%.

Black natural latex reclaimed rubber is made of waste rubber wire, rubber cups, waste rubber materials, waste latex products such as variegated waste latex gloves, etc., which are sorted and selected, disinfected and dried, crushed and desulfurized, filtered and squeezed E4LYY110 after pressing and molding, with the basic performance characteristics of natural rubber, high mechanical strength, good elasticity, aging resistance, plasticity and better than natural rubber, which can directly replace some natural rubber and neoprene rubber, styrene-butadiene rubber and use it to produce rubber V-belt cloth glue and reduce costs.

2. Rubber V-belt wrapping cloth layer glue mixed with black natural latex reclaimed rubber formula design points

(1) Vulcanization system: when black natural latex reclaimed rubber is used together with natural rubber and styrene-butadiene rubber to produce rubber V-belt cloth layer rubber, sulfur vulcanization system is mostly used; When latex reclaimed rubber is mixed with neoprene as the main raw material, the metal oxide vulcanization system is mostly used, and the amount of sulfur needs to be controlled and scorched when using sulfur.

(2) Reinforcing system: high wear-resistant carbon black such as N330 and semi-reinforcing carbon black such as N660 are used together, mostly filled with calcium carbonate, which gives the V-belt coating layer high mechanical strength and good processing performance.

(3) Softening plasticization system: it is recommended to use aromatic oil, pine tar and coumaron resin to improve the adhesion of the cloth layer; Control the amount of softener and plasticizer to avoid the problem of stickiness of the adhesive tape and affecting the operation; The plasticity of rubber is generally controlled in the range of 0.5-0.6.

3. Rubber V-belt wrapping cloth layer vulcanization formula mixed with black latex reclaimed rubber

30 parts of natural rubber, 20 parts of black natural latex reclaimed rubber, 50 parts of neoprene, 10 parts of zinc oxide, 1 part of stearic acid, 3 parts of magnesium oxide, 1 part of antioxidant A, 1 part of antioxidant D, 22 parts of carbon black N774, 15 parts of mixed carbon black, 30 parts of light calcium, 5 parts of pine tar, 4 parts of engine oil, 4 parts of DBP, 0.5 parts of accelerator CZ, 0.5 parts of sulfur; Total: 197 copies.

In actual production, ordinary rubber V-belt stretch layer glue, cord layer glue, compression layer glue and other parts can also be appropriately mixed with black natural latex reclaimed rubber, and we will continue to discuss related issues with you in the future.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits