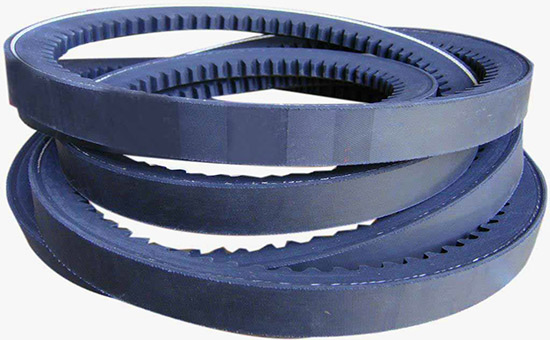

Rubber triangular belt is a transmission belt with an isosceles trapezoidal cross-section processed from rubber as the main raw material. It is widely used for power transmission on various types of electric motors and internal combustion engine driven machinery and equipment. Natural rubber has the characteristics of high strength and elasticity, making it an ideal raw material for producing ordinary rubber triangular belts. As a replacement raw material for natural rubber, natural latex recycled rubber 2SLYY424 can be used alone or in combination with natural rubber or other synthetic rubber to prepare different adhesive layers for triangular belts, effectively reducing raw material costs.

The rubber triangular belt mainly includes a compression layer, an extension layer, a cord layer, and a cloth covering rubber, and the performance requirements of different parts of the rubber material are different.

1. Practical formula for producing triangular belt compression layer adhesive using natural rubber/latex recycled adhesive

The rubber triangle belt compression layer adhesive needs to be subjected to periodic compression, and during use, it generates a lot of heat. It requires the rubber material to have some heat resistance, bending resistance, flexibility, low heat generation, small compression permanent deformation, sufficient hardness, and good adhesion with the cord fabric layer adhesive.

70 parts natural rubber, 30 parts latex recycled rubber, 6 parts zinc oxide, 2 parts stearic acid, 1.5 parts antioxidant D, 40 parts carbon black N330, 15 parts carbon black N774, 40 parts light calcium, 40 parts clay, 2 parts pine tar, 0.5 parts accelerator M, 1 part accelerator DM, and 3 parts sulfur; Total: 251 copies.

2. Practical formula for producing triangular belt extension layer adhesive using natural rubber/latex recycled adhesive

The stretching layer of the rubber triangle belt needs to withstand some of the tension during the bending of the triangle belt during operation, and can increase the elasticity of the V-belt. The rubber material is required to have good fatigue resistance, high elasticity, small deformation, and high tensile stress.

80 parts of natural rubber, 20 parts of latex recycled rubber, 5 parts of zinc oxide, 3.5 parts of stearic acid, 1.5 parts of antioxidant A, 1 part of antioxidant D, 75 parts of carbon black N330, 25 parts of light calcium, 5 parts of engine oil, 2 parts of coumarone resin, 0.5 parts of accelerator M, 0.02 parts of accelerator TMTD, and 3 parts of sulfur; Total: 221.52 copies.

3. Practical formula for producing triangular belt ply adhesive using natural rubber/latex recycled adhesive

The rubber triangular belt cord fabric layer rubber is a framework that bears the tensile force during operation. It requires the rubber material to have good resistance to bending fatigue, low heat generation, good adhesion with the cord fabric, heat resistance, aging resistance, and high tensile stress.

85 parts of natural rubber, 15 parts of latex recycled rubber, 10 parts of zinc oxide, 2.5 parts of stearic acid, 1.5 parts of antioxidant A, 1 part of antioxidant D, 10 parts of carbon black N330, 8 parts of carbon black N774, 13 parts of light calcium, 6 parts of coumarone resin, 0.5 parts of accelerator DM, 1 part of accelerator CZ, and 3 parts of sulfur; Total: 156.5 copies.

4. Practical formula for using natural rubber/latex recycled adhesive to produce triangular belt cloth covering adhesive

The rubber triangular belt fabric layer adhesive mainly serves to connect various components into a whole and protect other components from wear and erosion. It is required that the adhesive material has certain adhesion, wear resistance, heat resistance, aging resistance, and bending resistance, and has good adhesion performance with the fabric layer.

80 parts of natural rubber, 20 parts of latex recycled rubber, 5 parts of zinc oxide, 3 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant D, 12 parts of carbon black N330, 10 parts of carbon black N774, 45 parts of light calcium, 10 parts of activated calcium carbonate, 4 parts of coumarone resin, 1.5 parts of engine oil, 3 parts of pine tar, 0.5 parts of accelerator M, 0.5 parts of accelerator DM, 0.05 parts of accelerator TMTD, and 2.65 parts of sulfur; Total: 199.2 copies.

When using latex recycled adhesive to reduce costs for rubber triangular belts, the amount of latex recycled adhesive can be appropriately increased. In the future, the editor will continue to share with you the key production process points of using latex recycled adhesive and natural rubber to produce each layer of rubber triangular belt.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits