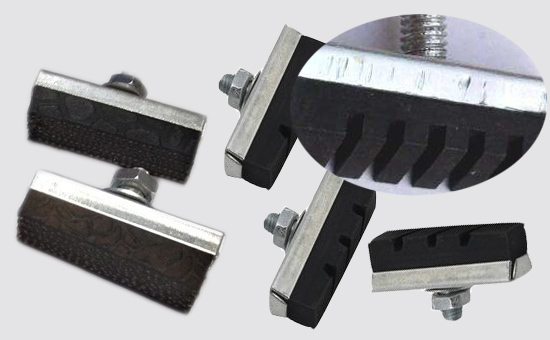

The rubber brake shoe can increase the friction to increase the friction, and finally achieve the braking effect; currently the rubber raw materials commonly used in the rubber brakes on the market are natural rubber, nitrile rubber and recycled rubber. Among them, natural rubber can enhance the braking performance, nitrile rubber can increase the toughness of the brake shoe, and recycled rubber can improve the process performance of the rubber compound and reduce the cost of raw materials. The rubber brake shoe manufacturer can choose a small amount of natural rubber and process it with a large amount of recycled rubber 1JLYY815.

1. Low-cost rubber brake skin reference formula

100 parts of natural rubber, 200 parts of tread reclaimed rubber, 400 parts of rubber reclaimed rubber, 8 parts of zinc oxide, 4 parts of stearic acid, 30 parts of carbon black, 160 parts of light calcium, 75 parts of rubber oil and 8 parts of accelerator. 8 parts of sulfur, total: 993 parts. (Vulcanization at 155 ° C for 4-5 minutes.)

2. The role of each compounding agent in the production of rubber brakes

When the tread reclaimed rubber and the rubber reclaimed rubber are used as the main raw materials, and a small amount of natural rubber is used to produce the low-cost rubber brake skin, the rubber product manufacturer uses the sulfur vulcanization system, and the accelerator can select the accelerator M, the accelerator DM and the accelerator TMTD. Appropriate amounts of zinc oxide and stearic acid can promote vulcanization.

The carbon black in the reinforcing system can significantly increase the hardness of the rubber brake shoe. The high wear-resistant furnace black can increase the tensile properties, tear resistance, wear resistance and elasticity of the rubber brake pad while increasing the hardness of the rubber; Filling further reduces costs.

When the rubber reclaimed rubber, tread reclaimed rubber and natural rubber are used together to produce low-cost rubber brakes, rubber manufacturers generally choose low-cost rubber oil to form a softening system, in which spindle oil and motor oil are good choices, and spindle oil is in rubber brakes. There is also good lubrication in production.

When producing rubber brake shoes with recycled rubber as the main raw material, rubber products manufacturers can choose the above production method, use the rubber glue reclaimed rubber, tire reclaimed rubber and a small amount of natural rubber, and can also completely use the tire tread reclaimed rubber or the tire. The tread reclaimed rubber and a small amount of natural rubber are used together to produce a rubber girder with higher quality. The type and amount of each compounding agent in the formula need to be adjusted in time according to the index of the reclaimed rubber and the proportion of the reclaimed rubber/natural rubber.

As a new raw material for reducing the production cost of rubber products industry, recycled rubber can significantly reduce the cost and improve the economic benefits of manufacturers in the production of rubber brake shoes. In this small series, I would like to remind everyone again: friends who use reclaimed rubber must carefully choose reclaimed rubber and cooperate directly with the regular reclaimed rubber factory to avoid the trouble of regenerating rubber quality fluctuation or reclaimed rubber out of stock for normal production.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits