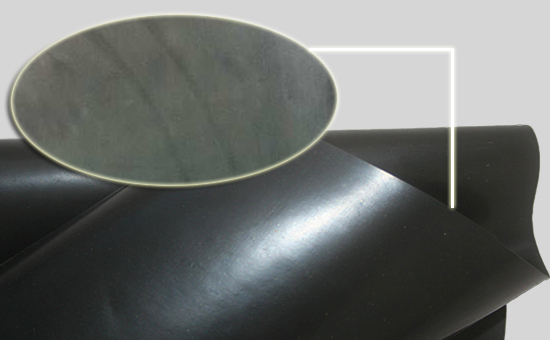

The use of tire reclaimed rubber production of plastic products can greatly reduce the cost of raw materials, tire reclaimed rubber in the production of low-grade ordinary rubber products, the main material. However, sometimes the rubber reclaimed rubber produced after the park even turned "white", and this is why?

Black plastic sheeting whitening is mainly caused by frosting on the surface of rubber products, such as the difference between the polarity of the recycled rubber compound and the selected chemical compound, which leads to the decrease of the solubility of the compounding agent in the rubber compound, and the compatibility of the two Poor sex mix system caused by instability, under certain conditions, mixing compound in the migration occurs, resulting in recycled plastic sheeting cream;

Or uneven mixing with the tire reclaimed rubber, poor dispersion, resulting in tire reclaimed rubber sheet local frost;

In addition, the compatibility of tire reclaimed rubber and compounding agent is good, but the amount of compounding agent does not exceed its saturated solubility in compound, and blooming problem also occurs.

Excessive use of various processing aids can also cause blooming phenomenon, such as sulfur, accelerators, activators, antioxidants can cause full discharge, especially the accelerator and curing agent too much, leading to rubber false saturation vulcanization, in nature The temperature of the molecule is still cross-linked, and after the completion of the cross-linked part of the material will precipitate the surface, so that the surface of recycled plastic sheet whitening; processing aids, migration aid, antistatic agents will cause the relocation of the discharge ; CaCO3 caused stress spray and so on.

Therefore, the production of rubber tire reclaimed rubber, we must design a reasonable reclaimed rubber tire recipes, repeated testing, careful selection of chemical additives such as curing agents, accelerators, processing aids, fillers and other product categories, strict control of chemical Auxiliary dosage, the implementation of full supervision of the production process to ensure that the tire reclaimed plastic sheet formula design is reasonable not because of the amount of blooming caused by frost phenomenon.

Tire renewable plastic sheet production process, accurate grasp of vulcanization time, curing temperature, the time is too long too short, the temperature is too low will cause vulcanization of rubber vulgar, vulcanization is not equal, leading to the surface of recycled plastic sheeting cream.

Blooming phenomenon occurs when the recipe design and process operation are correct. Considering the amount of paraffin in the reclaimed rubber sheet formula, paraffin wax will spit out the surface to form a kind of protective wax when used later. Prevention of plastic plate blooming phenomenon; cost permits, you can add the appropriate amount of anti-frost agent, such products are developed specifically for rubber products cream, the main role is to break down and inhibit the phenomenon of rubber products spit frost.

In addition, the quality of tire reclaimed rubber products, premature aging, migration will also result in tire reclaimed rubber sheet blooming cream, so the choice of reclaimed rubber tires should be cautious.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits