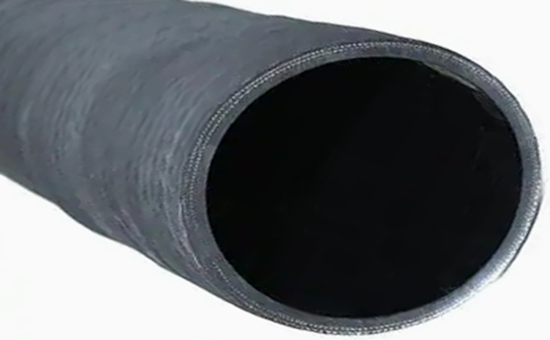

Polybutadiene rubber is polymerized from butadiene, with a cis-content of over 95%. The vulcanized rubber exhibits excellent cold resistance, wear resistance, and elasticity, generates little heat under dynamic load, and can be used alone or in combination with styrene-butadiene rubber and natural rubber to produce the inner, middle, and outer layers of fabric-reinforced suction hose. Proper addition of recycled tire rubber can further reduce raw material costs.

1. Vulcanization formulation for the inner layer of fabric-reinforced suction hose using polybutadiene rubber/natural rubber/recycled tire rubber

Polybutadiene rubber 30 parts, natural rubber 15 parts, recycled tire rubber 55 parts, zinc oxide 2.1 parts, stearic acid 1.2 parts, antioxidant A 0.2 parts, antioxidant D 0.4 parts, semi-reinforcing carbon black 10 parts, high abrasion carbon black 10 parts, clay 25 parts, calcium carbonate 25 parts, oil 6 parts, pine tar 5 parts, accelerator CZ 0.85 parts, sulfur 1.25 parts; total 187 parts.

2. Vulcanization formulation for the middle layer of fabric-reinforced suction hose using polybutadiene rubber/styrene-butadiene rubber/recycled tire rubber

Polybutadiene rubber 45 parts, oil-extended styrene-butadiene rubber 25 parts, recycled tire rubber 30 parts, zinc oxide 3.5 parts, stearic acid 1.5 parts, antioxidant D 2 parts, paraffin wax 0.7 parts, high abrasion carbon black 40 parts, calcium carbonate 78 parts, oil 11 parts, pine tar 6 parts, accelerator M 0.9 parts, accelerator DM 1.1 parts, sulfur 1.8 parts; total 246.5 parts.

3. Vulcanization formulation for the outer layer of fabric-reinforced suction hose using polybutadiene rubber/styrene-butadiene rubber/natural rubber/recycled tire rubber

Polybutadiene rubber 25 parts, oil-extended styrene-butadiene rubber 20 parts, natural rubber 25 parts, recycled tire rubber 30 parts, zinc oxide 3.5 parts, stearic acid 2.8 parts, antioxidant A 1 part, antioxidant D 0.5 parts, paraffin wax 0.5 parts, high abrasion carbon black 35 parts, calcium carbonate 60 parts, oil 18 parts, pine tar 7 parts, accelerator M 0.7 parts, accelerator DM 0.7 parts, sulfur 1.8 parts; total 231.5 parts.

.Different layers of fabric-reinforced suction hoses have varying performance requirements, and the proportion of recycled tire rubber used differs. Rubber hose manufacturers need to select the appropriate recycled tire rubber E5LYY520 according to specific physical property requirements, reasonably determine the mixing ratio of recycled rubber, and properly adjust the production formula to reduce raw material costs and energy consumption while maintaining the hose's performance.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits