Tire reclaimed rubber is a waste tire through crushing, desulfurization, refining and other processes to produce recycled rubber, with the basic performance characteristics of rubber, the price is much lower than new rubber, can be used alone or with natural rubber, synthetic rubber to produce rubber products, effectively reduce the cost of raw materials. The main raw materials for the production of tires are natural rubber, styrene-butadiene rubber, butadiene rubber, etc., and there is a certain gap among the physical and mechanical properties of tire reclaimed rubber and new rubber, can it be re-added to tire production?

1. The feasibility of tire reclaimed rubber for tire manufacturing

Can tire reclaimed rubber be used to make tires? The answer is yes. Tire reclaimed rubber has certain elasticity, mechanical strength and wear resistance, which can meet the performance requirements of tires. Although the key indicators such as tensile strength and tear elongation of tire reclaimed rubber are not as good as those of the original rubber, the tire reclaimed rubber has good compatibility with natural rubber, styrene-butadiene rubber, butadiene rubber, etc., and can be used in combination with the original rubber in an appropriate proportion, and low-cost, high-performance tires can be produced through reasonable formula design and process adjustment.

The tire is composed of a tire, an inner tube and a cushion belt, and the outer tire mainly includes three parts: carcass, tread and bead. Different vehicles have different tire performance requirements, and the proportion of tire reclaimed rubber is also different.

2. The main application range of tire reclaimed rubber in tires

(1) Tire tread rubber: The outermost layer of the tire is in contact with the road surface and the surface is printed with a pattern, which requires the rubber compound to have good elasticity, tensile strength, wear resistance, flexural resistance, low heat generation, etc. A small amount of tire reclaimed rubber and natural rubber can be used together in the processing of tire tread rubber, which reduces the cost and reduces the heat generation in the process of mixing, hot mixing, calendering, and extrusion, which is conducive to the smooth extrusion of the tread rubber.

(2) Tire sidewall rubber: The main function is to protect the tire carcass from mechanical damage and external moisture erosion, protect the carcass, and require the rubber material to have excellent flexural resistance, aging crack resistance and puncture resistance. It is recommended to choose high-strength tire tread reclaimed rubber in the tire sidewall rubber, which has high effective rubber hydrocarbon content and high mechanical strength, which can better meet the strict requirements of tire sidewall rubber for flexural resistance, aging crack resistance and puncture resistance, and ensure the performance and life of tire sidewall rubber.

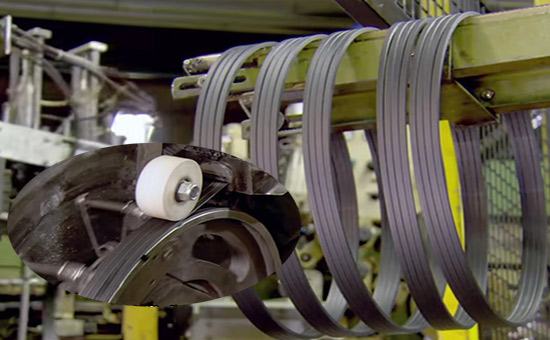

(3) Tire steel wire lagging rubber: the adhesive layer coated on the surface of the steel wire can enhance the combination of steel wire and rubber, provide mechanical protection and cushioning for the steel wire, and improve the strength, wear resistance and tear resistance of the tire. Tire steel wire lagging requires the compound to have good viscosity, appropriate hardness, suitable tensile strength and tear elongation. The appropriate use of tire reclaimed rubber in tire steel wire lagging can improve the vulcanization speed, the adhesion among rubber and steel wire, and the tensile strength, elongation at break, hardness and so on of vulcanized rubber are basically unchanged.

(4) Tire pad tape glue: located among the inner tube and the rim, it plays an important role in protecting the inner tube, reducing friction and blocking foreign objects. Tire pad tape rubber requires the compound to have good flex resistance, high tear resistance E4LYY1212 good aging resistance and suitable tensile strength. When tire reclaimed rubber is used in combination with natural rubber, styrene-butadiene rubber, butadiene rubber, etc. to make tire pad tape glue in an appropriate proportion, the mixing time can be appropriately extended, the mixing temperature can be increased, the rubber material can be evenly dispersed, and the performance of the finished tire pad rubber can be improved.

3. Practical formula for tire production mixed with tire reclaimed rubber

(1) Tire tread rubber mixed with tire reclaimed rubber vulcanization formula: 50 parts of natural rubber, 50 parts of butadiene rubber, 10 parts of tire reclaimed rubber, 4 parts of zinc oxide, 2.5 parts of stearic acid, 3 parts of antioxidant, 1.5 parts of paraffin, 58 parts of carbon black N220, 7 parts of mechanical oil, 0.85 parts of accelerator, 1.6 parts of sulfur; Total 188.45 copies.

(2) Tire sidewall rubber mixed with tire reclaimed rubber vulcanization formula: 35 parts of natural rubber, 25 parts of styrene-butadiene rubber, 40 parts of butadiene rubber, 15 parts of tire reclaimed rubber, 4 parts of zinc oxide, 3 parts of stearic acid, 3.5 parts of antioxidant, 1.5 parts of dispersant, 70 parts of carbon black, 6.5 parts of aromatic oil, 0.85 parts of accelerator, 1.6 parts of sulfur; Total 205.95 copies.

(3) Vulcanization formula of tire steel wire rubber mixed with tire reclaimed rubber: 50 parts of natural rubber, 50 parts of styrene-butadiene rubber, 30 parts of tire reclaimed rubber, 35 parts of carbon black N660, 80 parts of carbon black N750, 25 parts of clay, 10 parts of aromatic hydrocarbon oil, 0.5 parts of accelerator, 1 part of cobalt salt, 15 parts of others; Total 296.5 copies.

(4) Vulcanization formula of tire pad rubber mixed with tire reclaimed rubber: 30 parts of natural rubber, 60 parts of styrene-butadiene rubber, 10 parts of butadiene rubber, 150 parts of tire reclaimed rubber, 7 parts of active agent, 60 parts of carbon black, 50 parts of light calcium carbonate, 8 parts of aromatic oil, 7.5 parts of sulfur and accelerator, and 6.5 parts of others; Total 389 copies.

Although there are certain limitations on the use of tire reclaimed rubber to make tires, the application of tire reclaimed rubber in tire production is not limited to this by adjusting the formula and optimizing the production process.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits