Tire steel wire overcovering is a rubber layer wrapped on the surface of the steel wire, so that the steel cord and rubber are better combined, generally processed with natural rubber and styrene-butadiene rubber as the main raw materials; If the lagging performance of the steel wire does not meet the requirements, the tire will have the problem of bead bursting caused by the steel wire crushing during use. The main components of tire reclaimed rubber are natural rubber, synthetic rubber and carbon black, which have the basic performance characteristics of rubber, and can be used in the production of tire steel wire lagging to effectively reduce the cost of raw materials.

1. The main performance requirements of tire steel wire lagging

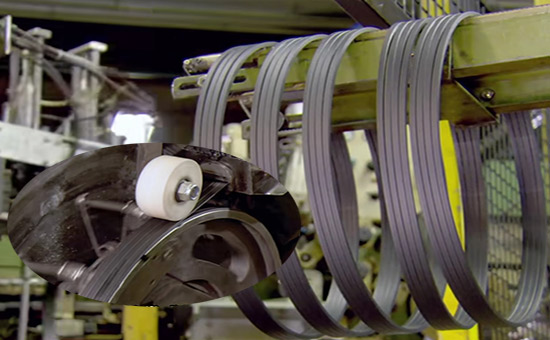

The steel wire lagging in the tire can provide mechanical protection and cushioning for the tire, and use the elasticity of the rubber to reduce the wear of the steel wire; The overmolded steel cord can improve the strength, wear resistance and tear resistance of the tire, make the tire more durable, and improve the overall performance and stability of the tire. Tire steel wire lagging requires good viscosity properties, appropriate hardness, tensile strength and elongation at break.

2. The influence of tire reclaimed rubber on the performance of steel wire lagging properties

When using natural rubber/styrene-butadiene rubber combined with rubber to produce tire steel wire rubber, the appropriate amount of tire reclaimed rubber is used in the steel wire rubber formula, the vulcanization speed is accelerated, the tensile strength, elongation at break, and hardness of vulcanized rubber are basically unchanged, the adhesion is significantly improved, and the aging resistance of vulcanized rubber is significantly better than that of rubber without reclaimed rubber; Improve the high-speed performance and durability of tires.

3. Tire steel wire covering is mixed with reclaimed rubber vulcanization formula

40 parts of natural rubber, 30 parts of styrene-butadiene rubber, 30 parts of high-strength tire reclaimed rubber, 30 parts of carbon black N660, 70 parts of carbon black N750, 1 part of cobalt salt, 20 parts of activated clay, 7 parts of aromatic oil, 0.4 parts of accelerator, 12 parts of other compounding agents.

4. Key points of formula design of tire steel wire lagging mixed with reclaimed rubber

When tire reclaimed rubber is used in combination with natural rubber and styrene-butadiene rubber to produce steel wire rubber, it is recommended to choose high-strength tire reclaimed rubber, which has higher mechanical strength; Using carbon black as a reinforcing agent, high wear-resistant carbon black, general-purpose furnace black, semi-reinforcing furnace black can be used together E4LYY1031 which can provide good tensile strength, wear resistance, flexural resistance and adhesion; Activated clay can enhance the stiffness of the compound and reduce costs; Aromatic oil can improve the fluidity and calendering properties of the compound, and pine tar has both softening and anti-aging properties.

The rational use of tire reclaimed rubber in the production of tire steel wire lagging can not only reduce the cost of raw materials, but also improve the performance of rubber processing technology and finished products, so as to achieve a win-win situation of economic benefits and product performance; In the future, Xiaobian will continue to discuss with you the mixing skills and practical formulas of tire reclaimed rubber in other parts of tires.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits