Using waste tires as raw materials, the tire reclaimed rubber processed through sorting, crushing, desulfurization, refining and other processes has the basic performance characteristics of rubber, low price and stable performance, and can effectively reduce the cost of raw rubber in the production of rubber products. Tire reclaimed rubber can be used alone, or combined with natural rubber, styrene-butadiene rubber, butadiene rubber, etc., reasonable design of formula, strict control of the production process, can meet the diversified needs of rubber materials in different application scenarios in the automotive industry.

1. Application of tire reclaimed rubber in automobile tires

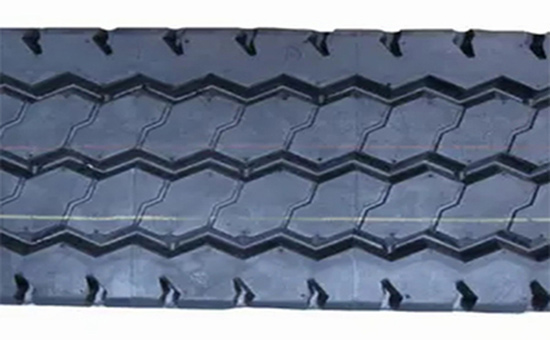

In the production of automobile tires, tire reclaimed rubber can be used in combination with natural rubber and synthetic rubber to produce tire tread, sidewall, cushion belt, wire ring rubber, triangle rubber strip, etc. For example, a small amount of tire reclaimed rubber is mixed with tire tread rubber, which can improve the wear resistance, aging resistance and tear resistance of the tread rubber, reduce the rolling resistance of the tire, reduce fuel consumption and noise, prolong the service life of the tire, and improve the driving economy and comfort of the vehicle.

Ultra-fine tire reclaimed rubber has the characteristics of high fineness, good elasticity and small specific gravity, and can be mixed into a small amount of automotive inner tube or tubeless tire innerliner rubber formula, which can effectively reduce the cost of raw materials under the premise of ensuring product quality.

2. Application of tire reclaimed rubber in auto parts

Automobile seals are important components to ensure the tightness and waterproofness of automobiles. Tire reclaimed rubber can be used to make automotive seals, such as door seals, window seals, engine compartment seals, etc. Reclaimed rubber has good elasticity and sealing, which can effectively prevent water, dust and noise from entering the interior of the car.

Automobile shock absorber is an important component to ensure the driving stability and comfort of the car. Tire reclaimed rubber can be used to manufacture rubber parts of automobile shock absorbers, such as shock absorber spring pads, shock absorber sealing rings, etc. Reclaimed rubber has good elasticity and shock absorption properties, which can effectively reduce the vibration and bumps during the driving of the car.

3. Application of tire reclaimed rubber in automotive interiors

Automotive interior parts are an important factor affecting the comfort and aesthetics of automobiles. Tire reclaimed rubber can be used in the processing of automotive interior parts, such as car seat cushions, car carpets, car dashboards, etc., effectively reducing the production cost of automotive interior parts.

200-300 kinds of rubber parts (excluding rubber tires) will be used in a car, and the amount of rubber parts used in some trucks and industrial vehicles even reaches more than 600. As a new type of recycled rubber raw material, tire reclaimed rubber E4LYY419 can significantly reduce the production cost of auto parts compared with natural rubber and synthetic rubber, and is widely used in the automotive industry.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits