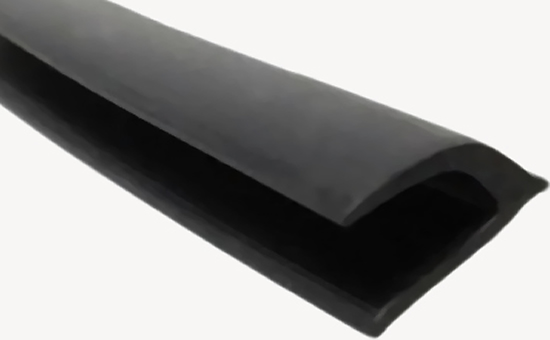

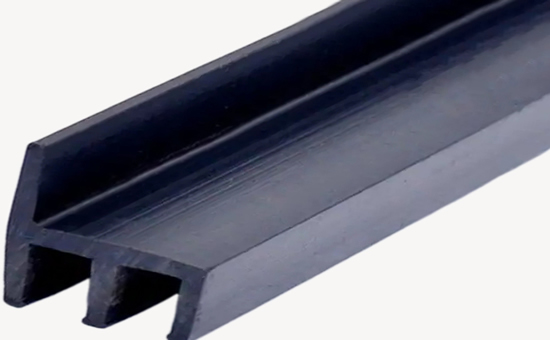

The rubber sealing strip mainly uses the elasticity of lips, cavities, flanges and other parts to generate contact pressure with the surface of their contacts to achieve sealing. It can be used in cars, building doors and windows, household appliances, etc. to prevent external dust, air, water, etc. from entering the system. Natural rubber, styrene butadiene rubber, nitrile rubber, ethylene propylene rubber, butyl rubber, etc. can be used to produce rubber seals. Can recycled tire rubber, as a substitute for high priced raw rubber, be used in the production of rubber seals? What problems should we pay attention to?

In actual production, the recycled tire rubber can be used alone or with natural rubber and general synthetic rubber to produce rubber sealing strips, reducing the cost of raw materials. When using recycled tire rubber to produce low-cost rubber seals, rubber seal manufacturers need to pay attention to the following issues.

1. When rubber sealing strip is mixed with recycled tire rubber, attention shall be paid to the recycled tire rubber index

When selecting the recycled rubber for rubber sealing strip, attention should be paid to the tensile strength, elongation at break, fineness mesh, environmental protection standards, etc.

Select the recycled tire rubber that is closer to the tensile strength, elongation at break and other indicators of the rubber sealing strip, and more recycled rubber can be mixed to reduce the cost. It is recommended to use reclaimed rubber 2ELYY1223 for rubber sealing strips with high mechanical strength requirements. Select 60-80 mesh fine recycled tire rubber and ultra-fine recycled tire rubber, and the surface of extruded rubber strip will be more smooth and bright. When the rubber sealing strip is required to be environmentally friendly and tasteless, it is recommended to use odorless tire regeneration rubber and environment-friendly tire regeneration rubber, which are free of pollution, radiation, penetration, non-toxic and tasteless.

2. Pay attention to the amount of recycled tire rubber when rubber sealing strips are mixed with recycled tire rubber

When using recycled tire rubber to reduce the production cost of rubber sealing strip, rubber product manufacturers need to reasonably determine the amount of recycled tire rubber according to the technical requirements of the sealing strip and the performance indicators of the recycled rubber. Generally, low cost ordinary rubber sealing strips can be completely used with recycled tire rubber or used with a small amount of natural rubber, effectively reducing the cost of raw rubber; The reclaimed tire rubber can also be used with styrene butadiene rubber, cis polybutadiene rubber, isoprene rubber, latex reclaimed rubber, isoprene reclaimed rubber, etc. to produce rubber sealing strips.

3. The rubber sealing strip is mixed with the vulcanization formula of recycled tire rubber

60 natural rubber, 40 polybutadiene rubber, 280 recycled tread rubber, 18 zinc oxide, 1.8 stearic acid, 4 antioxidant A, 3 paraffin wax, 40 carbon black N330, 100 light calcium, 38 engine oil, 38 industrial grease, 0.9 accelerator D, 1.5 accelerator DM, 5.2 accelerator M, 0.3 accelerator TMTD, and 7.3 sulfur; Total: 638 copies.

The raw materials of recycled tire rubber processed from waste tires come from a wide range of sources, and the product price is low. The mixing of various solid sealing strips and sponge sealing strips in the production can not only reduce the raw material cost and production energy consumption of the sealing strips, but also solve some waste tires. Later, Xiaobian will continue to share with you the key processing points and precautions for the production of rubber sealing strips from recycled tire rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits