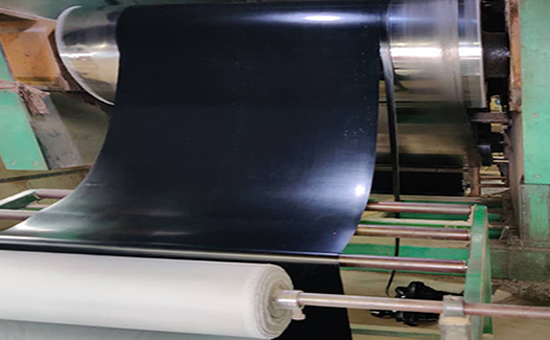

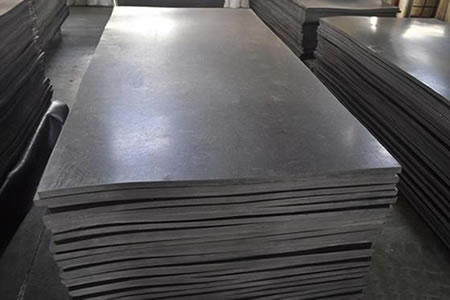

Rubber sheet is processed with rubber as the main raw material. It can be divided into ordinary rubber sheet, acid and alkali resistant rubber sheet, oil resistant rubber sheet, conductive rubber sheet, anti-static rubber sheet, flame retardant rubber sheet, etc. according to the use performance. Different types of rubber sheets use different types of rubber. Regenerated tire rubber is a renewable rubber resource for processing waste tire rubber powder. It has a wide source of raw materials and low product price. It can be mixed into various rubber sheet formulas at an appropriate proportion. While ensuring the quality of acid and alkali resistant rubber sheets, it can reduce the cost of raw materials by more than 15% and save labor and electricity costs. It has achieved good economic and social benefits in terms of low-carbon and environmental protection

1. Mix recycled tire rubber to produce acid and alkali resistant rubber plate formula

100 natural rubber, 100 recycled tire rubber, 7 zinc oxide, 2.5 stearic acid, 1 antioxidant D, 5 paraffin wax, 40 carbon black N330, 232.2 barite powder, 8 black ointment, 0.5 accelerator D, 0.7 accelerator M, 0.1 accelerator TMTD, and 3 sulfur; Total: 500 copies

The acid and alkali resistance of rubber sheet mainly depends on the performance of rubber itself. The chemical stability of rubber decreases with the increase of rubber unsaturation. Natural rubber has good alkali resistance, but is not resistant to concentrated strong acid; Most diene rubbers have a certain resistance to common acids and alkalis. When using natural rubber to produce acid and alkali resistant rubber sheets, rubber product manufacturers can not only mix recycled rubber appropriately, but also use it together with styrene butadiene rubber, cis polybutadiene rubber, etc. when necessary, and use chemically inert fillers such as clay, barium sulfate, talcum powder, diatomite, etc. to further improve the chemical stability of rubber sheets

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits