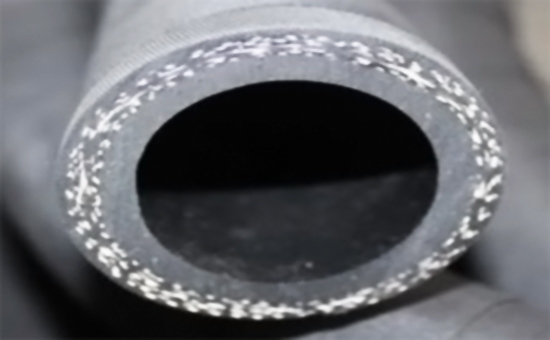

The outer rubber of the cloth sandwiched water delivery hose is in direct contact with the external environment, which can protect the inner structure from damage. It has strict requirements on the light resistance, weather resistance, flexion flexibility, wear resistance and tear resistance of the rubber. It can be properly mixed with tire recycled rubber to reduce the cost and improve the process performance of the rubber. When designing the outer rubber formula of the cloth sandwiched water delivery hose containing tire recycled rubber, the rubber product manufacturer needs to consider the service environment of the cloth sandwiched water delivery hose and select appropriate additives to further optimize the comprehensive performance of the water delivery hose

1. The reference formula for mixing recycled rubber in the outer layer of cloth water delivery hose is

50 parts of natural rubber, 50 parts of styrene butadiene rubber, 50 parts of tire recycled rubber, 4 parts of zinc oxide, 1.5 parts of stearic acid, 2.5 parts of antioxidant, 2 parts of paraffin, 40 parts of N330, 110 parts of light calcium, 40 parts of clay, 18 parts of rubber oil, 3.4 parts of promoter and 2.6 parts of sulfur; Total: 374 copies

2. Design basis of outer rubber formula of cloth water delivery hose

(1) Vulcanizing AIDS: in actual production, the rubber content of the outer rubber of the rubber pipe is generally controlled at 30-35%. The dual purpose of reducing cost and improving processing performance can be achieved by using recycled rubber appropriately. When sulfur vulcanization is used, accelerator M can be used as the main accelerator to quickly promote the vulcanization crosslinking reaction, and a small amount of aftereffect accelerator DM can be used to inhibit the occurrence of early vulcanization; During vulcanization, the vulcanization speed is stable and the vulcanization flatness is good. A small amount of accelerator DM can also better adjust the vulcanization speed and match the vulcanization process of other parts of the hose

(2) Anti aging additive: paraffin can be used as internal release agent and physical anti-skid agent in rubber products. Excessive amount of paraffin in the inner layer of cloth sandwiched water delivery hose will affect the adhesion of the adhesive, so the amount should be controlled 1-1.5 parts. Different from the inner rubber layer, the amount of paraffin in the outer rubber layer of natural rubber / styrene butadiene rubber / tire recycled rubber water delivery hose can be appropriately increased and controlled at 2-3 parts. The use of chemical antioxidant A and antioxidant D can further improve the aging resistance, ozone resistance, flexion flexibility and sunlight resistance of the outer rubber layer of the rubber hose, and prolong the service performance and service life of the cloth sandwiched water delivery rubber hose

(3) The tear resistance of the outer layer of the natural rubber coating such as y266 rubber coating and the reclaimed rubber coating can be significantly improved due to the higher tear resistance of the rubber coating and the reclaimed rubber coating of the natural rubber coating, such as the rubber coating of y266 rubber coating, which have higher requirements for the tear resistance of the rubber coating Aging resistance, etc

The tensile strength of the outer rubber of the cloth clamping water delivery hose produced with the above formula is about 10MPa and the elongation at break is 440-450%. The rubber product manufacturer can appropriately increase or decrease the amount of tire recycled rubber according to the actual demand, so as to reduce more raw material costs on the premise of ensuring the quality

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits