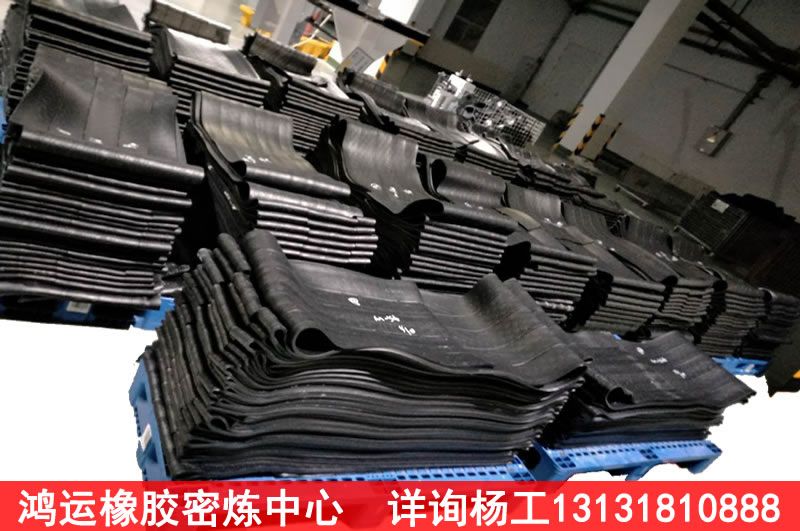

Mixing is one of the most important and prone to quality fluctuations in rubber processing, which directly affects the quality of products. Therefore, doing a good job in rubber mixing is crucial for rubber enterprises

As a rubber mixer, in order to do a good job in rubber mixing, one should master the mixing process and the mixing characteristics of various types of rubber. In addition, one also needs to think and operate carefully. Only rubber mixers who possess both knowledge and hands-on skills are considered qualified

Whether it is recycled rubber or raw rubber, ensuring the quality of mixed rubber should achieve the following four points:

1. Mix a small but effective amount of compounding agent evenly, otherwise it may lead to coking or insufficient vulcanization of the rubber material

2. Strictly follow the mixing process and feeding sequence for operation

3. Properly controlling the mixing time can affect the plasticity of the mixed rubber if it is too long or too short

4. Carbon black and fillers that are widely used should not be thrown away at will, and the material tray should be fully used and cleaned

There are many factors that affect the quality of mixing, including uneven dispersion of additives, frost spraying, and coking. These problems can be found through visual inspection (detailed introduction in the next article)

Some rubber workers have two wrong ideas esyy517:

1. It is believed that the longer the mixing time, the higher the quality of the adhesive. In fact, if the mixing time is too long, it will reduce the plasticity of the mixed rubber and affect the quality

2. It is believed that less accumulation of glue on the roller will accelerate the feeding speed. Actually, it is not correct. Insufficient accumulation of glue will cause the powder to be compressed into flakes and fall. It needs to be re added and the mixing time extended to increase working strength. Excessive accumulation of glue can also slow down the feeding speed and affect mixing

Therefore, there should be an appropriate amount of adhesive accumulation on the roller during mixing.During mixing, on the one hand, the powder is mechanically squeezed into the adhesive, and on the other hand, the adhesive forms folds under mechanical action, causing the powder to be drawn into the adhesive. This can shorten the mixing time, reduce work intensity, and achieve good quality of the mixed rubber

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits