Compared with the production of reclaimed rubber, the processing technology of processing waste rubber products into rubber powder is simpler and the production process is more environmentally friendly. Waste rubber powder is widely used in rubber and non-rubber fields, and foam plastic is one of them. In actual production, thermoplastics such as polystyrene, polyurethane, and polyvinyl chloride can be used in the production of foam; adding an appropriate amount of waste rubber powder in the preparation of various foams can improve the process, improve performance, and reduce costs. Multiple purposes.

1. Rubber powder/polypropylene to prepare foam

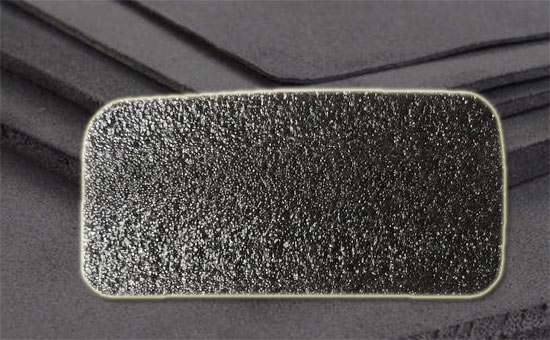

Polypropylene is a polymer prepared by the addition polymerization of propylene. It has good plasticity, high mechanical strength, excellent wear resistance, chemical resistance, heat resistance, and electrical insulation. It is widely used in machinery, automobiles, electronics, and construction. And other fields. Using rubber powder and polypropylene together, under the action of supercritical carbon dioxide, a foamed plastic material with a microporous structure can be prepared. The increase in the amount of rubber powder will reduce the pore size of the foam material and increase the pore density and relative density, so waste The amount of rubber powder needs to be controlled reasonably.

When using rubber powder and polypropylene to prepare foamed plastics, an appropriate amount of foaming agent can also be added to the rubber powder/polypropylene blend material. When the microcellular foam material is prepared by the injection process, the content of rubber powder and foaming agent has a great influence on the pore size and tensile strength of the blended foam material. In actual production, the use of rubber powder and polypropylene blends to prepare foam plastics must comprehensively consider the saturation temperature, foaming temperature, etc., to ensure that the foam is uniformly foamed, and the pore size, shape and relative density meet relevant requirements.

2. Rubber powder/polyurethane to prepare foam

The full name of polyurethane is polyurethane, soft polyurethane has good resilience, excellent mechanical properties, and has significant sound insulation, heat insulation and shock absorption effects. The waste rubber powder itself has good elasticity. Using about 20 parts of surface-modified rubber powder in the soft PU foam can further improve the resilience and uniformity of the foam 2LLYY721, reduce the cost, and improve the soft PU foam. Plastics are cost-effective and realize the recycling of waste rubber resources.

In actual production, waste tire rubber powder can also be combined with polyether polyol, surfactant and toluene diisocyanate to prepare polyurethane foam.

Compared with pure polymer, foam plastic has smaller specific gravity, higher strength, stronger impact load absorption, better heat and sound insulation performance, and can be used in various applications. Adding an appropriate amount of rubber powder, such as tire rubber powder, to the foam plastic material preparation process can not only improve the elasticity and mechanical properties of the foam plastic, but also reduce the cost of raw materials, solve the environmental pollution problem of some waste rubber resources, and contribute to economic and environmental development. There are multiple benefits, which can further promote the development of rubber powder production technology and expand the scope of application of rubber powder in foam.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits