Butyl rubber has excellent air tightness, good heat resistance and chemical corrosion resistance, and is widely used in industrial rubber products. The sponge rubber processed with butyl rubber as the main raw material has good elasticity, sound insulation and shock absorption effect, wear resistance and heat resistance, and is highly praised by users. However, in actual production, the vulcanization rate of butyl rubber is too slow, and the vulcanization rate and the foaming speed are difficult to match. The problem that the cell breaks after foaming and shrinks when the die is produced often occurs. How to solve 1JLYY930?

Butyl rubber is an elastomer composed of isobutylene and a small amount of isoprene. The double bond content is extremely low and the degree of unsaturation is low. Compared with the high unsaturation rubber, the vulcanization rate is about 3 times slower. Therefore, when using butyl rubber to prepare sponge rubber, the matching of vulcanization speed and foaming speed becomes a problem. At this time, rubber manufacturers may use butyl rubber together with other types of butyl rubber to improve the vulcanization rate of butyl rubber.

1. Combination of butyl rubber and chlorobutyl rubber

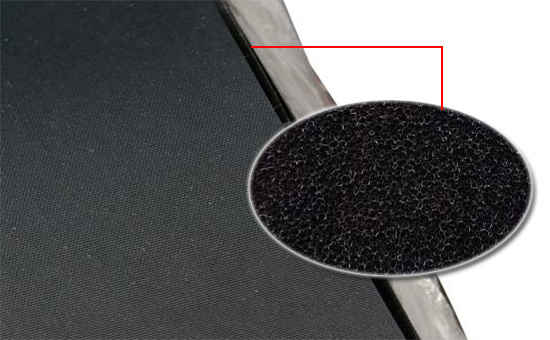

Chlorinated butyl rubber is a butyl rubber halogenated product obtained by introducing chlorine gas into a butyl rubber solution, retaining the original double bond structure of butyl rubber, low gas permeability, good shock absorption, heat resistance and aging resistance. Compared with butyl rubber, the vulcanization speed is faster, and it can also be co-vulcanized with other rubbers. The vulcanized rubber has better heat resistance and smaller compression set. Therefore, butyl sponge rubber product manufacturers can add appropriate chlorobutyl rubber to the butyl rubber-based sponge rubber material to improve the vulcanization rate of the butyl rubber.

When butyl rubber and chlorobutyl rubber are used together to prepare a sponge rubber material, the addition ratio of butyl rubber/chlorinated butyl rubber is generally controlled to about 3:1. Sulfur, accelerator TMTD, accelerator MZ and zinc oxide are selected. Stearic acid is combined with a large amount of heavy calcium and appropriate amount of aromatic oil. The foaming system of baking soda and petrolatum is used to adjust the foaming speed of butyl sponge rubber by adjusting the amount of compounding agent in the vulcanization system.

2. Butyl rubber and butyl reclaimed rubber are used together.

The butyl reclaimed rubber on the market is mainly composed of butyl inner tube reclaimed rubber, which retains the basic performance characteristics of butyl rubber. In the production process, it undergoes intense processing of various processes such as crushing, desulfurization, smelting, filtration and molding. The plasticity, fluidity and shrinkage are better than those of butyl rubber. The vulcanization speed is faster, the vulcanization flatness is better, and the chance of vulcanization reversion is smaller. Therefore, the butyl sponge rubber product manufacturer can also use the butyl rubber and the butyl reclaimed rubber to prepare the sponge rubber material, thereby improving the vulcanization rate of the butyl rubber and further reducing the raw material cost.

The butyl rubber sponge compound formula can also be used in a proper amount of chlorinated butyl reclaimed rubber processed from used medical cap caps to improve the vulcanization speed and cost.

When using chlorobutyl rubber, butyl reclaimed rubber or chlorinated butyl reclaimed rubber to improve the vulcanization speed of butyl sponge rubber, the rubber product factory must reasonably control the addition ratio of chlorinated butyl rubber and reclaimed rubber to satisfy the product. Other performance requirements increase vulcanization speed and reduce raw material costs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits