The raw materials of the nitrile reclaimed rubber are the sub-brand nitrile rubber, water fishing glue, waste nitrile gloves, etc. The quality of the nitrile reclaimed rubber processed by different manufacturers using different raw materials is very different, in order to better judge the nitrile regeneration. The quality of rubber products, rubber products manufacturers can conduct a small number of samples for scientific testing before selecting products.

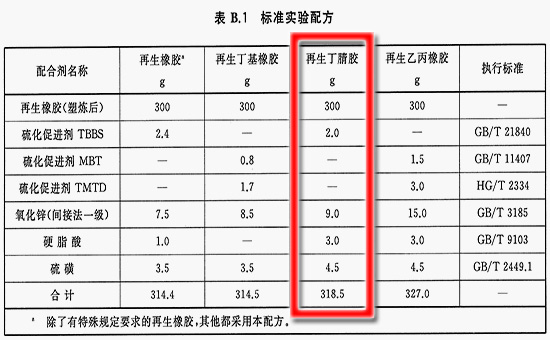

Rubber products manufacturers must carry out scientific and reasonable quality testing of nitrile reclaimed rubber according to the standard test formula in GBT 13460-2016 General Specification for Recycled Rubber: nitrile recycled rubber, 300g; vulcanization accelerator TBBS, 2.0g; zinc oxide ( Indirect method first), 9.0 g; stearic acid, 3.0 g; sulfur 4.5 g; total, 318.5 g.

Nitrile reclaimed rubber quality testing program

1. Mastication: In the laboratory at room temperature of 23 °C, the temperature of the open type rubber mixing machine that meets the requirements of GB/T 6038 is (40±5) °C, the roll distance is (1.50±0.10) mm, and the two baffles The distance between (150±20)mm (the roller temperature of the other procedures except the roller distance and the distance between the two baffles are set accordingly)

Take 310 g of the nitrile recycled rubber sample, put the sample into the rubber mixer and completely pass the roller 3 times. After the mastication, the rubber material is placed on a flat, clean and dry metal surface and cooled to room temperature.

2, mixing

According to the standard test formula of the nitrile reclaimed rubber, weigh 300g of the regenerated rubber sample after the mastication into the adjustment mixer, repeat the 3/4 cutter, fold the lower piece and then roll the roller to make the sample evenly wrapped on the roller; According to the remixing rubber mixing sequence, the prepared compounding agent is successively added, and each of the compounding agents is repeatedly alternately made into a 3/4 cutting knife, and the compounding agent of the sprinkling floor plate is recovered to the stacking glue in a time interval of 20 seconds in the continuous cutting knife. in. When there is no obvious free powder on the surface of the accumulated glue or the roller, the whole piece is cut and folded, the mixture is scrubbed with the folded sample, the compounding agent scattered on the chassis of the rubber mixing machine is adsorbed, and then vertically put into the rubber mixing machine. After the compounding agent is kneaded uniformly, the mixture is thinned and discharged.

Recycled rubber mixing sequence: accelerator [folding the next piece, mixing time 1.0min, roll distance (1.5 ± 0.10) mm] → zinc oxide [folding the next piece 1 time, rubber mixing duration 2.0min, roll distance (1.5±0.10)mm】→ Stearic acid [folding the next piece, mixing time 1.0min, roll distance (1.5±0.10)mm]→sulfur [folding down the film 2 times, rubber mixing duration 1.5min, Roller distance (1.5±0.10)mm】→thin pass [folding down the number of times 3 times, rubberizing duration 1.5min, roll distance (0.80±0.20)mm] → filming [folding the next piece 1 time, rubber mixing duration 1.0min, roll distance (1.50~2.00) mm], the mixing process was folded 9 times in total, and the rubber mixing duration was 8.0 min.

After mixing, the rubber is placed on a flat, clean, dry metal surface and cooled to room temperature. The cooled rubber is wrapped in aluminum foil to prevent contamination by other substances.

3. Vulcanization: The vulcanization temperature (145±1) °C was kept unchanged, and the regenerated rubber vulcanized test piece was prepared under the vulcanization time of 10 min, 15 min and 20 min respectively.

4. Measurement: According to GB/T 2941, the tensile strength and elongation at break of the recycled rubber vulcanized sample were determined according to GB/T528, and the optimum vulcanization time of the three vulcanization times was taken.

The above test formula only tests the basic parameters of the nitrile reclaimed rubber. If the nitrile reclaimed rubber is used to produce special-purpose rubber products, more precise quality inspection is required.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits