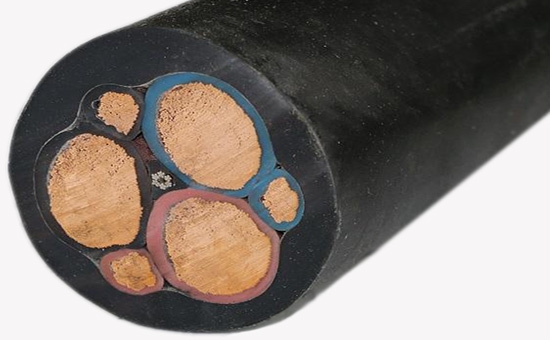

Rubber cables use rubber as the insulation layer and sheath. The cable insulation layer and sheath require rubber materials to be wear-resistant and aging resistant. They are often processed from natural rubber, styrene-butadiene rubber or ethylene-propylene rubber as the main raw materials, and some are resistant to acids and alkalis. Oil-resistant, flame-retardant rubber cables require special rubber. In actual production, oil-resistant nitrile rubber can be combined with latex reclaimed rubber in a suitable ratio to prepare special cable sheaths, which can effectively reduce the cost of raw materials under the premise of ensuring product quality.

1. Advantages of combined use of nitrile rubber and latex reclaimed rubber

Nitrile rubber has excellent oil resistance, abrasion resistance, and heat resistance. When combined with latex reclaimed rubber, it can further improve the impact resistance of the rubber cable sheath and reduce the cost of raw materials. In actual production, the combined use ratio of nitrile rubber and latex reclaimed rubber 2YLYY520 is determined according to the use occasions of the rubber cable sheath, performance requirements and the basic indicators of latex reclaimed rubber; proper adjustment of the rubber cable formula can effectively improve the heat resistance and corrosion resistance of the rubber , Anti-aging performance, etc., to avoid swelling of the rubber skin.

When using nitrile rubber and latex reclaimed rubber to prepare rubber cable sheath, it is recommended to use nitrile rubber/latex reclaimed rubber in a ratio of 1:2, and the amount of the two should be increased or decreased according to actual needs. When producing light-colored and colored rubber cable sheaths, white latex reclaimed rubber is generally used.

2. Commonly used auxiliary materials for the production of cable sheath of nitrile rubber/latex reclaimed rubber

When nitrile rubber and latex reclaimed rubber are used in the production of rubber cable sheath, carbon black is often used for reinforcement (white carbon black is recommended for light-colored cable sheath), such as low structure and high wear resistance carbon black N326. The material has good reinforcement effect and low heat generation. The use of titanate coupling agent can reduce the amount of rubber and antioxidant, and improve the abrasion resistance and aging resistance of the cable sheath.

Combined use of nitrile rubber/latex reclaimed rubber The vulcanization system for preparing rubber cable sheath can combine sulfur and dibenzoyl peroxide to improve the mechanical strength, heat resistance and fatigue resistance of the cable sheath, and the product service life is longer.

When nitrile rubber and latex reclaimed rubber are used together to produce rubber cable sheaths, fused silica powder, silicone resin, etc. can also be used, and an appropriate amount of antioxidants can be used. In actual production, the variety and amount of compounding agent in the cable sheath for different applications are different, and the manufacturer can determine it according to actual needs. It should be noted that when nitrile rubber/latex reclaimed rubber is used to prepare light-colored rubber cables, it is recommended to choose environmentally friendly latex reclaimed rubber that will not cause discoloration and migration, and use environmentally friendly additives, especially rubber oil and antioxidants.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits