Engineering rubber is used in construction, bridges, roads, railways, subways, culverts and other fields play a damping, noise reduction, protection and other effects of rubber products, such as common bridge bearings, railway pillow, rubber water stop, etc. , Such products on the strong demand for rubber, so many manufacturers are in the engineering rubber products using high-strength reclaimed rubber, both to ensure the quality of engineering rubber, but also reduce raw material costs.

Engineering rubber need to bear a great deal of weight, so rubber raw materials must be wear-resistant shock absorption, bearing capacity. Take the rubber bridge support as an example: The bridge support needs to bear all the pressure, shear force and flexural force from the static load and dynamic load, it will transmit these forces to the pier, with the appropriate displacement beam; In this process , The rubber bridge bearing can absorb part of the vibration, reduce the impact of dynamic load on the bridge structure and piers, reduce noise, ensure bridge safety and extend the service life. Here comes the question: Maybe you have a question: High strength tire reclaimed rubber in renewable resources is strong, but when it is used in the production of engineering rubber products (including all rubber products), it has poor elasticity, large flex cracking, and its own defects Can not be ignored, then why a lot of engineering rubber is high-strength reclaimed rubber production?

High-strength reclaimed rubber generally waste tire tread rubber as raw material processing and production, to know that the tire tread is the tire with the highest content of rubber, wear-resistant properties of the best parts, so the tire reclaimed rubber produced high strength, good elasticity , The proportion of small, low Mooney viscosity, easy processing, is widely used in high strength and high wear-resistant rubber products. Engineering rubber on the rubber raw material requirements are very high, related to a variety of construction safety, an accidental will have serious consequences. Therefore, the use of high-strength reclaimed rubber production engineering rubber can be used in combination with other rubber ways to improve the reclaimed rubber itself defects.

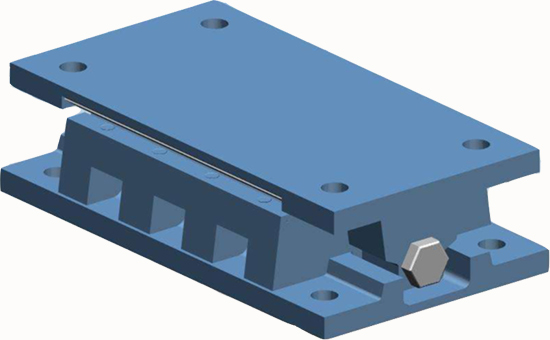

For example, common common slab rubber bearings are generally produced using natural rubber. However, the cost of natural rubber is too high. The use of an appropriate amount of high-strength tire reclaimed rubber that is close to the bearing index not only can reduce the production cost of the slab rubber bearing, but also Improve the rubber bearing's wear resistance and flex resistance while ensuring the original quality.

In addition, formula design of rubber products is particularly important when using recycled rubber in engineering rubber. Reasonable formula design for rubber products includes high-strength reclaimed rubber dosage, vulcanization system design, filling system coordination, and anti-aging system protection; rubber product engineers can design the most cost-effective engineering rubber product formula for customers' needs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits