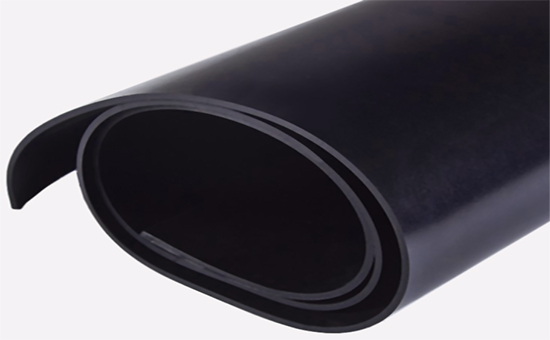

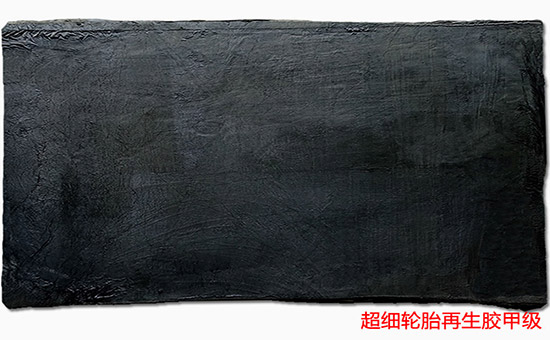

Rubber sheets are mainly made of rubber as the main raw material, and can be divided into ordinary rubber sheets, acid and alkali resistant rubber sheets, oil resistant rubber sheets, heat resistant rubber sheets, conductive rubber sheets, flame retardant rubber sheets, wear-resistant rubber sheets, etc. According to their performance requirements, different types of rubber raw materials need to be used in different usage scenarios. In actual production, tire recycled rubber, as a substitute for high priced raw rubber, can be added to rubber plates in an appropriate proportion, effectively reducing raw material costs while ensuring the performance of the rubber plates.

1. Vulcanization formula for ordinary industrial rubber plate mixed with tire recycled rubber

(1) 30% -40% rubber content of ordinary industrial rubber plate mixed with tire recycled rubber formula: 100 parts of natural rubber, 40 parts of tire recycled rubber, 6 parts of zinc oxide, 2.5 parts of stearic acid, 1.5 parts of antioxidant D, 20 parts of carbon black N774, 185 parts of stone powder, 10 parts of pine tar, 0.6 parts of accelerator D, 1.2 parts of accelerator M, and 2.5 parts of sulfur; Total: 369.3 copies.

(2) 20% -30% rubber content of ordinary industrial rubber plate mixed with tire recycled rubber formula: 50 parts of natural rubber, 50 parts of cis-1,4-polybutadiene rubber, 100 parts of tire tread recycled rubber, 5 parts of zinc oxide, 1.5 parts of stearic acid, 1.5 parts of antioxidant A, 1 part of paraffin, 35 parts of carbon black N330, 185 parts of stone powder, 4 parts of coumarone resin, 1.1 parts of accelerator DM, 1 part of accelerator M, 0.2 parts of accelerator TMTD, and 3.1 parts of sulfur; Total: 438.4 copies.

2. Acid and alkali resistant rubber plate mixed with tire recycled rubber vulcanization formula

100 parts natural rubber, 100 parts recycled tire tread rubber, 7 parts zinc oxide, 2.5 parts stearic acid, 1 part antioxidant D, 5 parts paraffin, 40 parts carbon black N330, 232.2 parts barite powder, 8 parts black ointment, 0.5 parts accelerator D, 0.7 parts accelerator M, 0.1 parts accelerator TMTD, and 3 parts sulfur; Total: 500 copies.

3. Oil resistant rubber plate mixed with tire recycled rubber vulcanization formula

100 parts of nitrile rubber, 50 parts of recycled tire tread rubber, 5 parts of zinc oxide, 1 part of antioxidant D, 100 parts of carbon black N774, 35 parts of clay, 35 parts of dibutyl phthalate, 0.4 parts of accelerator D, 1 part of accelerator M, and 2.6 parts of sulfur; Total: 330 copies.

In actual production, tire recycled rubber can also be added to rubber plates such as wear-resistant rubber plates, conductive rubber plates, and insulation rubber plates in an appropriate amount. Recycled rubber 2SLYY420 can also be used together with plastic materials to produce various types of rubber plates. In the future, the editor will continue to share with you the vulcanization formulas and production process points of other rubber plates used in the production of tire recycled rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits