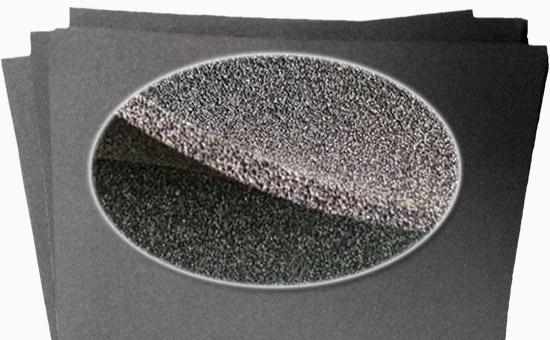

Foamed board has the characteristics of good elasticity, low density, and flex resistance, and has remarkable effects of shock absorption, sound insulation and heat insulation, and is widely used in various fields. In actual production, tire reclaimed rubber products processed from waste rubber tires have a wide range of raw materials and low product prices. They can be used to prepare low-cost foamed sheets, which effectively improve the economic benefits of manufacturers. When using tire reclaimed rubber to prepare foamed boards, choosing the right tire reclaimed rubber is the basis for ensuring the performance and life of the foamed boards.

1. Consider the basic indicators of reclaimed rubber

When using tire reclaimed rubber to produce low-cost foamed sheets, the manufacturer should select the tire reclaimed rubber closest to its indicators according to the basic index requirements of the foamed sheet, so as to reduce the cost and ensure the comprehensive performance of the foamed sheet 2YLYY525. From the perspective of production technology, selecting high-fineness and no impurities in reclaimed tire rubber can provide a good foundation for uniform foaming and smooth molding of the foamed sheet. Generally, it is recommended to use reclaimed tread rubber with a size of 60-80 mesh.

2. Consider the environmental performance of reclaimed rubber

In the actual application process, if the foamed sheet is used indoors or in direct contact with people, it is recommended to choose odorless reclaimed rubber or environmentally friendly tire reclaimed rubber that can provide relevant odorless and environmental protection test reports to avoid irritation during use of the foamed sheet Sexual odor, avoid harmful substances such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls and polybrominated diphenyl ethers from affecting human health. At present, the universal environmental testing standard in the world is the EU RoHS directive.

3. Reclaimed rubber can be used together with original rubber

When using reclaimed tire rubber as the main raw material to produce foamed sheets, rubber product manufacturers can add a small amount of natural rubber or styrene-butadiene rubber to the formula to further improve the elasticity, mechanical strength, flexibility, and abrasion resistance of the foamed sheet. In actual production, when reclaimed rubber is used together with a small amount of raw rubber to produce foamed sheets, the raw rubber needs to be masticated in advance, and it can be mixed with tire reclaimed rubber after full mastication to jointly prepare foamed sheets with better comprehensive indicators. .

When using tire reclaimed rubber to produce low-cost foamed sheets, manufacturers not only need to select suitable tire reclaimed rubber products, but also need to rationally design the foamed sheet formula, appropriately adjust the production process, and further optimize the quality of the finished foamed sheet. The editor has the opportunity to Continue to share with you the foam board formulation design and production process skills.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits