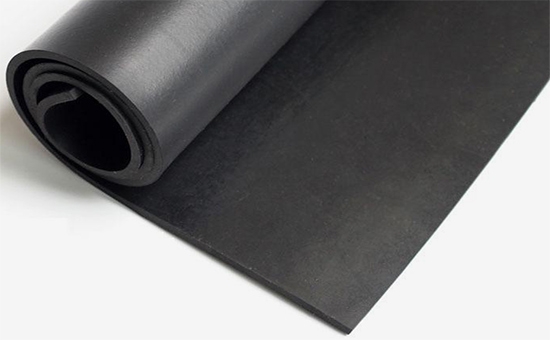

The effective rubber hydrocarbon content of tire reclaimed rubber is about 30%, and it can be used alone or in combination with styrene butadiene rubber and butadiene rubber to produce various types of rubber sheets. Ordinary rubber sheets are mostly industrial rubber sheets, which are general-purpose rubber sheets.They work in water and air.The rubber content is low, and the rubber material has mechanical strength and heat resistance. , The aging resistance performance is not high. Extensive use of reclaimed tire rubber to produce ordinary rubber sheets with low rubber content can effectively reduce the cost of raw materials.

1. Reclaimed tire rubber and a small amount of raw rubber to produce common rubber sheet reference formula

1800 parts of reclaimed tire rubber, 50 parts of styrene butadiene rubber, 50 parts of butadiene rubber, 30 parts of zinc oxide, 12 parts of stearic acid, 10 parts of antioxidants, 12 parts of paraffin wax, 90 parts of carbon black, 200 parts of clay, and 1050 calcium carbonate Parts, 20 parts of pine tar, 20 parts of industrial grease, 4.5 parts of accelerator, 12 parts of sulfur; total: 3360.5 parts.

The above formula contains about 20% of glue, and the finished product index meets the basic performance and index requirements of ordinary rubber sheet.

2. Cooperate with common rubber sheet vulcanization system that uses a large amount of reclaimed tire rubber

A large amount of tire reclaimed rubber is used to prepare ordinary industrial rubber sheets. Generally, traditional sulfur vulcanization systems are used with accelerator DM and accelerator TMTD. The accelerator DM and the accelerator TMTD are used together in a ratio of 4:5. During vulcanization, the scorching time of 2YLYY413 is longer, the vulcanization speed is faster, and the elongation at break and tensile strength of the vulcanized rubber are higher. In actual production, when the amount of TMTD is greater than the amount of DM, an appropriate increase in the amount of DM can delay the sulfur rate, and continue to increase the amount of DM can quickly activate the vulcanization system.

3. A common rubber sheet reinforcement and filling system that uses a large amount of reclaimed tire rubber

When tire reclaimed rubber is combined with a small amount of styrene butadiene rubber and butadiene rubber to produce ordinary rubber sheets, appropriate use of high wear-resistant carbon black such as N330 can improve the tensile properties, tear resistance, wear resistance and elasticity of the rubber sheets. Light calcium carbonate can improve the tensile strength, abrasion resistance and tear strength of the rubber compound during use; the cost of heavy calcium is low, and when combined with other reinforcing agents or fillers, it can adjust the performance of vulcanized rubber and further reduce ordinary rubber sheets. cost.

When tire reclaimed rubber is combined with a small amount of styrene-butadiene rubber/butadiene rubber to prepare ordinary industrial rubber sheets, choosing the right reclaimed rubber is the most important thing. The effective rubber hydrocarbon content of the tread reclaimed rubber is higher and the mechanical strength is greater. Ordinary rubber is recommended. The board uses tread reclaimed rubber. In actual production, rubber product manufacturers also need to pay attention to the choice of anti-aging system and softening system. The editor has the opportunity to continue discussing with you about the preparation of common industrial rubber sheets from tire reclaimed rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits