Compared with natural rubber and styrene-butadiene rubber, butadiene rubber has better wear resistance, elasticity, low temperature performance and aging resistance; The recycled rubber is made of waste rubber products with high butadiene rubber content or the leftovers produced in the production of butadiene rubber products, and is produced by opction, classification, crushing, screening, desulfurization, tableting and other processes, which retains the basic performance characteristics of butadiene rubber, and can be used alone or in combination with butadiene rubber, natural rubber, styrene-butadiene rubber, etc. to produce various rubber products to reduce raw material costs.

1. Rubber tires

Tires are mainly made of rubber (natural or synthetic rubber such as butadiene rubber, styrene-butadiene rubber, etc.), carbon black, steel wire and other chemical additives, including outer tires (consisting of carcass, tread and bead), inner tube and pad (tubeless tires do not have inner tubes and pads). Butylene recycled rubber can be used with natural rubber, styrene-butadiene rubber, butadiene rubber and other raw rubber to produce tire tread rubber and carcass rubber, and must pay attention to whether the compound is evenly dispersed when mixing.

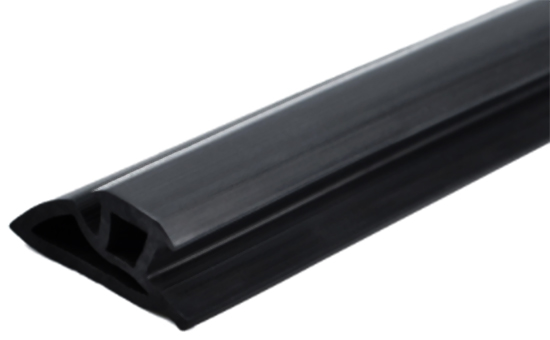

2. Extruded products

Rubber extrusion products are rubber products made through the extrusion process, and the rubber must be preheated before extrusion to make the rubber soft and easy to extrude, so as to obtain rubber products with smooth surface and accurate dimensions. In actual production, butadiene rubber can be used in conjunction with oil-filled styrene-butadiene rubber E5LYY417 to manufacture extruded products, which can obtain compounds with better processing performance (extrusion speed, shrinkage and surface properties) and elasticity. Compared with the original rubber, the recycled rubber has good fluidity and plasticity, which can replace some butadiene rubber to produce various extruded products, reduce the cost of raw materials and further improve the processing process performance of the rubber.

3. Rubber sole

The sole processed with rubber as the main raw material has the characteristics of good elasticity, high comfort, wear resistance and anti-slip, and the cold resistance, wear resistance and elasticity of butadiene rubber vulcanization have excellent cold resistance, wear resistance and elasticity, and can maintain good performance for a long time in the production of rubber soles. Using recycled butylene rubber instead of the appropriate proportion of butadiene rubber to produce soles can reduce raw material costs while maintaining good resilience, softness, and shock absorption effect of rubber soles.

4. Adhesive tape

Butadiene rubber is used to make adhesive tape, and vulcanized rubber has good elasticity and ozone resistance. When used in conjunction with oil-filled styrene-butadiene rubber, the amount is generally 15%-30%, and the viscosity of the rubber decreases with the increase of the combined use ratio, the better the processing performance, the tensile strength and hardness of the vulcanized rubber are enhanced, and the permanent deformation, compression set and rebound deformation are better, while the ozone resistance remains unchanged. The recycled butadiene rubber has good compatibility with styrene-butadiene rubber, and can be used with butadiene rubber and styrene-butadiene rubber to make adhesive tape, reducing raw material costs and production energy consumption.

5. Cushioning material

The main function of cushioning materials is to absorb impact energy, reduce vibration, and protect equipment or the human body from external forces. Recycled butadiene rubber has good elasticity and wear resistance, and can be used alone or in combination with butadiene rubber, natural rubber, and styrene-butadiene rubber to produce cushioning materials, such as industrial cushioning/shock absorbing pads, auto parts cushioning parts, etc., to reduce the cost of raw rubber.

After manual option, classification and cleaning process, it is first put into a high-speed elastomer shredder to crush into granules, and then grinded to 60 mesh and then vibrated through a vibrating screen to remove impurities, and the dynamic desulfurization tank is pressed and formed after high-temperature desulfurization. The product has the advantages of high cleanliness, good fineness, small taste, cold resistance and wear resistance, and is easy to use with natural rubber, neoprene or nitrile rubber, and some of the mixed recycled rubber can reduce the cost of raw materials by about 15% under the premise of ensuring quality.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits