In addition to vulcanizing agents and accelerators, rubber fillers, softening plasticizers, and antioxidants are also indispensable in the production of rubber products. Foaming agents and foaming additives are also used in foamed rubber products. The improper use of these compounding agents in rubber products can also cause ejection problems. So what are the reasons for the ejection of the above compounding agents? Which method should be used to effectively prevent the compounding agent from spraying from the surface of the rubber product?

3. Reasons and solutions for the ejection of rubber filler in rubber products

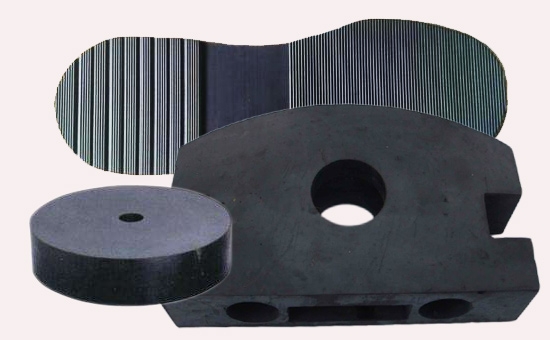

Carbon black, white carbon black, calcium carbonate, magnesium carbonate, clay, talc, etc. are commonly used as fillers in the production of rubber products. Among them, white carbon black, calcium carbonate, magnesium carbonate, etc. are all inorganic fillers. Their morphology, physical properties, and The rubber is very different, and its compatibility with rubber is much worse than that of organic fillers. It is easy to spray from the rubber surface when the amount is large.

To use inorganic fillers to reinforce or fill rubber products, rubber product manufacturers need to control the amount of inorganic fillers; or use inorganic coupling2LLYY0320 agents such as silane coupling agents for surface treatment to improve the affinity of rubber molecules and filler particles. When the two are combined through a chemical reaction to form a network structure, it is difficult for the inorganic rubber filler to migrate to the surface of the rubber product, which can effectively prevent the inorganic filler from spraying out.

4. Reasons and solutions for spraying of softened plasticizer in rubber products

Softeners and plasticizers can reduce the intermolecular forces of rubber in the production of rubber products, improve the fluidity and plasticity of the rubber, and then provide a better basis for subsequent molding processes such as calendaring and extrusion. The solubility of various softening plasticizers in the same rubber is different, and the solubility of the same rubber for different softening plasticizer products is also different. Rubber product manufacturers need to choose the appropriate variety of softening plasticizers according to actual needs, and reasonably control the amount. Avoid squirting. For example, naphthenic oil can be used in ethylene-propylene rubber products.

Theoretically, softeners and plasticizers with higher viscosity and more complex molecular structure have better compatibility with rubber, and it is not easy to bleed out of the product surface during use.

5. Reasons and solutions for anti-aging agent spraying in rubber products

Antioxidants in rubber products can delay the aging time of rubber products. In actual production, the combination of multiple antioxidants can effectively prevent the antioxidants from precipitating on the surface of rubber products.

At present, the rubber raw materials commonly used in the rubber product industry can be divided into natural rubber, synthetic rubber, and recycled rubber. Among them, recycled rubber can reduce the production cost of rubber products. It should be noted that, because the molecular structure and performance characteristics of recycled rubber are different from the corresponding original rubber, in the formulation of rubber products containing recycled rubber, the type and amount of compounding agents must be reasonably adjusted to avoid excessive amounts of compounding agents Or the phenomenon that the surface is ejected due to improper use.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits