Butyl rubber has excellent heat resistance, ozone resistance, moisture resistance, and good electrical properties. It is an ideal raw material for producing high and low voltage cables, cable sheaths, and other electrical insulation materials. Butyl reclaimed rubber can replace some of the raw rubber in the production of cables and cable sheaths, effectively reducing the cost of raw materials. In actual production, selecting appropriate butyl reclaimed adhesive and adjusting the formulation can further optimize product quality while reducing the production cost of high and low voltage cables and sheaths.

1. Selection skills of raw materials for butyl reclaimed rubber production of high and low voltage cables and sheaths

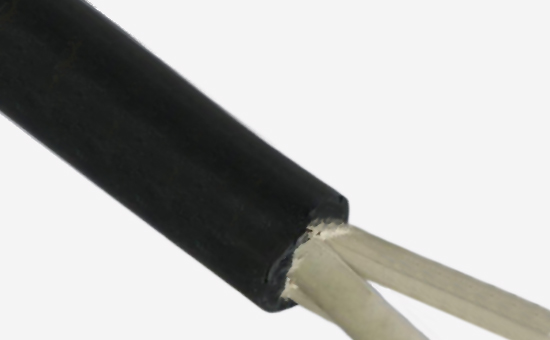

When using butyl reclaimed rubber to reduce the cost of raw materials for high and low voltage cables and sheaths, it is recommended to consider the technical indicators of rubber products and select butyl reclaimed rubber that is close to the physical indicators of the products; To ensure the smooth molding and smooth surface of the high and low voltage cable sheath, it is recommended to choose ultrafine filtered butyl reclaimed adhesive. When producing high-voltage wires and cables, it is recommended to use butyl reclaimed rubber together with low unsaturated butyl raw rubber to meet the demand for high ozone resistance; When producing low voltage wires, it is recommended to use it together with high unsaturated butyl rubber for better heat aging resistance.

2. Key points for coordination of butyl reclaimed rubber additives in the production of high and low voltage cables and sheaths

The commonly used curing systems for the production of rubber products using butyl rubber/butyl reclaimed rubber blends include sulfur curing system, resin curing system, and quinone oxime curing system. The use of butyl rubber/reclaimed rubber 2SLYY317 to produce wire insulation compounds that are often in the operating temperature range of 80-90 ℃ can use a resin curing system, typically dominated by quinone oxime and sulfur curing systems.

The quinone oxime vulcanization system is often used in the production of high-voltage wire and cable insulation materials using butyl rubber/butyl reclaimed rubber blends. The commonly used combinations are p-quinone oxime/accelerator DM/lead tetroxide, p-dibenzoyl benzoquinone oxime/lead tetroxide; Adding about 0.5 part sulfur yellow can prevent scorching. When using sulfur vulcanization for butyl rubber cable compound, it is recommended to use a low sulfur vulcanization system, and the combination of sulfur and accelerator TMTD/ZDC/DM is appropriate.

When p-quinone dioxime is used as an active agent in the curing system for preparing cable compound from butyl rubber/butyl reclaimed rubber, zinc oxide will not affect the scorching of the compound; Adding about 5 parts zinc oxide to the p-dibenzoyl benzoquinone dioxime vulcanization system can significantly shorten the scorching time. When producing high and low voltage wires and cables with butyl rubber, adding 0.2-0.5 parts of stearic acid can effectively avoid scorching the adhesive roller, sticking the mold core, and sticking the outlet mold.

To improve the moisture resistance and electrical insulation properties of butyl rubber/butyl reclaimed rubber composite cable compound, and improve the pressing process of the compound, calcined clay can be used as a filler, combined with a small amount of talc powder and calcium carbonate. Using petroleum jelly and paraffin as plasticizers can improve the processing performance of butyl rubber compound. The use of antioxidant D in the production of high and low voltage cables and sheaths using butyl reclaimed rubber has a good protective effect against heat, oxygen, flexion, cracking, and general aging factors.

When using butyl reclaimed rubber to reduce the production cost of high and low voltage cables and sheaths, rubber product manufacturers must select appropriate indicators of butyl reclaimed rubber based on actual needs, reasonably determine the proportion of butyl reclaimed rubber to be used, and appropriately adjust the rubber product formula and production process parameters. The editor will continue to discuss relevant issues with you in the future.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits