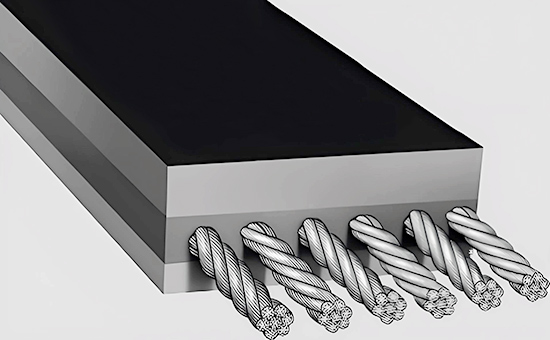

The rope core adhesive of ordinary steel wire rope core conveyor belt requires good adhesion and tear resistance with steel wire, generally made of natural rubber, styrene-butadiene rubber or natural rubber/styrene-butadiene rubber and glue as raw materials, and the glue content rate is about 50%. Recycled rubber is the main raw material to reduce the cost of rubber products, can it be used in the processing of ordinary steel wire rope core conveyor belt core adhesive? Which recycled glue is suitable? How much is better to mix? How to design a wire rope core conveyor belt rope core adhesive formulation with recycled rubber?

1. Commonly used recycled rubber varieties of ordinary steel wire rope core conveyor belt core adhesive

(1) Fine tire recycled glue

Tire recycled rubber is processed from waste tire rubber powder as raw material, the main components are natural rubber, general synthetic rubber and carbon black, the effective rubber hydrocarbon content is about 30%, and natural rubber, styrene-butadiene rubber is well compatible, which can replace some of the original rubber to produce ordinary wire rope core conveyor belt core glue and reduce the cost of raw rubber. The higher the fineness of tire recycled compound, the easier it is to disperse evenly during the mixing process, which can improve the processing performance of ordinary steel wire rope core conveyor belt core adhesive, and the wear resistance and tear resistance of the finished product are better.

(2) Black natural latex recycled glue

Natural latex recycled rubber is processed from waste natural rubber, waste latex and its products (such as waste rubber cups, rubber wires, waste latex gloves, latex finger covers, etc.) as raw materials, with the basic performance characteristics of natural rubber, E5LYY324 effective rubber high hydrocarbon content, good elasticity, strong strength, can directly replace some natural rubber to produce ordinary wire rope conveyor belt rope core glue, and effectively reduce the cost of raw materials under the premise of ensuring cost performance. Black latex recycled rubber with the same index is cheaper and more cost-effective than white natural recycled rubber.

(3) Styrene-butadiene recycled rubber

Styrene-butadiene recycled rubber is made of elastic tape, hose as the main raw material, adding part of the waste tire top glue, after material selection and crushing, magnetic separation and vibrating screen remove impurities, dynamic desulfurization tank high temperature desulfurization after refining the lower sheet, the processing performance is close to natural rubber, with tear resistance, wear resistance and anti-aging, high plasticity, easy mixing, low heat generation, low temperature flexibility and other characteristics, which can replace part of the styrene-butadiene original rubber to produce ordinary steel wire rope core conveyor belt core adhesive, further reduce costs.

2. Key points of the formula of recycled rubber mixed with the core adhesive of ordinary steel wire rope core conveyor belt

(1) Vulcanization system

When natural rubber/recycled rubber, natural rubber/styrene-butadiene rubber/recycled rubber are used to produce ordinary steel wire rope core conveyor belt rope core glue, the ordinary sulfur-accelerator system is mostly used, the amount of sulfur is controlled at 2-3 parts, and the amount of sulfonamide accelerators such as accelerators NS, NOBS, etc. is used in the form of 1.2-1.5 parts; With a small amount of activated magnesium oxide, it can inhibit vulcanization, reduce cross-linking density, increase the free sulfur content, and form more chemical bonds with the galvanized layer to improve the adhesive strength of the adhesive material.

(2) Adhesive system

To improve the bonding strength of the adhesive layer of the ordinary wire rope core conveyor belt and the wire rope, the "methane white" bonding system and the cobalt salt bonding system can be used, of which the cobalt salt can significantly improve the bonding strength. In actual production, copper-plated steel wires are mainly based on the meta-methane white system, or a small amount of cobalt salt binder is used; Galvanized steel wire is mainly made of cobalt salt binder, or a small amount of m-methyl white system is used.

(3) Reinforce the filling system

When the core glue of ordinary steel wire rope core conveyor belt is mixed with recycled glue to reduce the cost, carbon black N330 is used as the main reinforcer, combined with a small amount of silica, which is beneficial to the bonding strength, and the amount of carbon black is recommended to be no more than 10 parts. It is recommended to use it with medium and ultra-wear-resistant carbon black and mixed gas carbon black, and the dosage is recommended to be controlled below 50 parts.

(4) Softening and plasticizing system

When natural rubber/recycled rubber, natural rubber/styrene-butadiene rubber/recycled rubber are used together to produce rubber products, the amount of softener and plasticizer is second only to raw rubber and carbon black. It is recommended to use coumaron resin with good heat resistance, and can be used with a small amount of chlorinated paraffin if necessary.

For example, when natural rubber and fine tire recycled rubber are used together to produce rope core glue, it is recommended to control the amount of recycled rubber to be controlled below 20%, and latex recycled rubber can replace more parts of natural rubber; In the future, the editor will continue to share with you the practical formula of natural rubber, styrene-butadiene rubber and recycled rubber and the production of ordinary wire rope core conveyor belts.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits