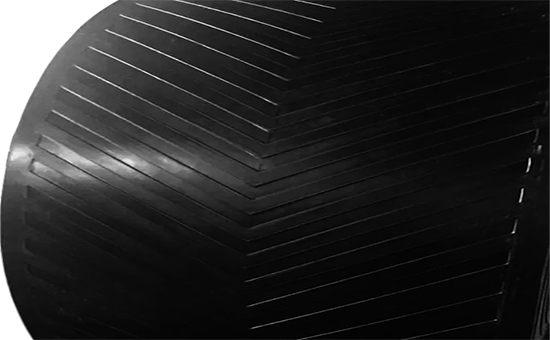

Ordinary rubber conveyor belts, rubber V belts, and rubber sheets are mostly processed with natural rubber as the main raw material. The appropriate amount of tire reclaimed rubber can effectively reduce production costs. In actual production, the performance requirements of different parts of the rubber conveyor belt, V-belt and rubber plate are different, and the manufacturer needs to design the formula reasonably according to the specific technical index requirements.

7. Reference formula for rubber conveyor belt mixed with tire reclaimed rubber

75 parts of natural rubber, 25 parts of cis-butadiene rubber, 30 parts of tire reclaimed rubber, 4.4 parts of zinc oxide, 3 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant D, 2 parts of paraffin, 48 parts of carbon black N330, 15 parts of engine oil, 0.8 parts of accelerator M, 1 part of accelerator CZ, 2 parts of sulfur; total: 208.2 parts. 【Ordinary conveyor belt covering glue formula】

65 parts of natural rubber, 70 parts of tire reclaimed rubber, 4.5 parts of zinc oxide, 2 parts of stearic acid, 1 part of antioxidant D, 25 parts of carbon black N774, 70 parts of heavy calcium, 2.5 parts of pine tar, 15 parts of petroleum asphalt, accelerator Agent M 0.6 parts, sulfur 3 parts; total: 258.6 parts. [Ordinary conveying and rubbing formula]

8. Reference formula for rubber V-belt mixed with tire reclaimed rubber

100 parts of natural rubber, 30 parts of tire reclaimed rubber, 3 parts of zinc oxide, 2.5 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant D, 40 parts of carbon black N774, 20 parts of aerated carbon black, 39 parts of light calcium parts, 4 parts of coumarone, 5 parts of heavy oil, 0.6 parts of accelerator DM, 1 part of accelerator CZ, 2.6 parts of sulfur; total: 249.7 parts. [Ordinary V-belt compression layer glue]

100 parts of natural rubber, 20 parts of tire reclaimed rubber, 3 parts of zinc oxide, 2.5 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant D, 50 parts of carbon black N774, 40 parts of aerated carbon black, 20 parts of light calcium parts, 4 parts of coumarone, 4 parts of DBP, 0.6 parts of accelerator DM, 1 part of accelerator CZ, 2.6 parts of sulfur; total: 249.7 parts. [Ordinary V-belt stretch layer glue]

100 parts of natural rubber, 30 parts of tire reclaimed rubber, 5 parts of zinc oxide, 2.5 parts of stearic acid, 1 part of antioxidant A, 1 part of antioxidant D, 20 parts of carbon black N774, 28 parts of light calcium, 4 parts of coumarone , 3 parts of heavy oil, 1.4 parts of accelerator CZ, 2.5 parts of sulfur; total: 198.4 parts.

9. Reference formula for rubber sheet mixed with tire reclaimed rubber

100 parts of natural rubber, 40 parts of tire reclaimed rubber, 6 parts of zinc oxide, 2.5 parts of stearic acid, 1.5 parts of antioxidant D, 20 parts of carbon black N774, 180 parts of stone powder, 10 parts of pine tar, 0.6 parts of accelerator D, Agent M 1.2 parts, sulfur 2.4 parts; total: 364.2 parts. 【30-40% rubber sheet formula】

100 parts of natural rubber, 30 parts of tire reclaimed rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 1 part of antioxidant A, 1 part of paraffin, 35 parts of carbon black N330, 96 parts of light calcium, 112 parts of barite powder, liquid 14 parts of coumarone, 0.7 parts of accelerator D, 1.5 parts of accelerator DM, 1.8 parts of sulfur; total: 400 parts. 【20-30% rubber sheet formula】

Different rubber layers of natural rubber conveyor belts, different rubber layers of natural rubber V-belts, and natural rubber sheets in different occasions have different specific performance requirements. Rubber product manufacturers must reasonably mix tire reclaimed rubber according to actual needs. In actual production, the rubber products that can be mixed with tire reclaimed rubber are more than that. Later, the editor will continue to share with you the mixing skills of tire reclaimed rubber in various natural rubber products.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits