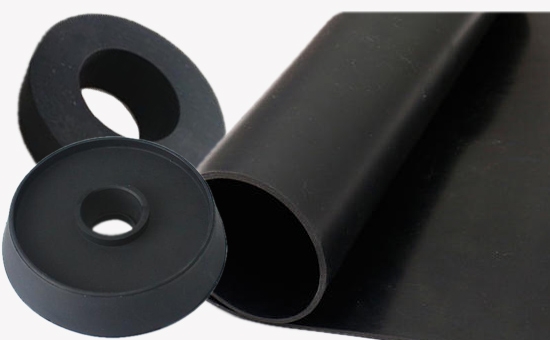

The performance characteristics of reclaimed latex rubber made from waste natural rubber/latex and its waste products are basically the same as those of natural rubber. It can fully or partially replace natural rubber to produce tire tyres, conveyor belts, rubber soles, rubber plates, seals, etc. Effectively reduce the cost of raw materials under the premise of quality. In actual production, tire tyres, conveyor belts, shoe soles, dynamic sealing strips and other products have high requirements on the wear resistance of rubber materials. Rubber product manufacturers need to take measures to further improve the wear resistance of latex reclaimed rubber.

1. Appropriate use of butadiene rubber and styrene butadiene rubber

Butadiene rubber vulcanizate has excellent wear resistance and high elasticity, and styrene butadiene rubber has better wear resistance, heat resistance and aging resistance than natural rubber. When using latex reclaimed rubber alone or latex reclaimed rubber in combination with natural rubber to produce rubber products, rubber product manufacturers can add an appropriate amount of styrene butadiene rubber or butadiene rubber to the formula to improve the wear resistance of the product. In actual production, due to the poor process performance of butadiene rubber, when using butadiene rubber to improve the wear resistance of latex reclaimed rubber products, the dosage should be controlled to coordinate the relationship between wear resistance and processing performance.

2. Adjust the vulcanization system

In the production of latex reclaimed rubber products, the crosslinking density of vulcanizates and the type of crosslinking bonds affect the wear resistance of the rubber. The abrasion resistance of reclaimed latex rubber after vulcanization with sulfur + accelerator CZ system is better. Choosing DTDM+S (less than 1 part) + accelerator NOBS vulcanized latex reclaimed rubber vulcanizate 2LLYY1126 abrasion resistance and other mechanical properties can achieve a more ideal state. Under normal circumstances, when latex reclaimed rubber or latex reclaimed rubber/natural rubber is used for sulfur vulcanization, the amount of sulfur is controlled between 1.5-2.5 parts.

3. Adjust the reinforcement filling system

Carbon black is a commonly used reinforcing agent in the production of rubber products. In the production process of latex reclaimed rubber products, the wear resistance of the reclaimed rubber vulcanizate increases with the decrease of the carbon black particle size and the increase in surface activity and dispersibility. The reclaimed rubber vulcanizate with reinforced carbon black has better wear resistance . White carbon black can improve the abrasion resistance of light-colored latex reclaimed rubber products, especially high temperature abrasion resistance. When carbon black is used for reinforcement, the amount of carbon black is controlled between 40-50 parts; the white carbon black treated with silane coupling agent can significantly improve the wear resistance of the rubber compound.

4. Adjust other coordination systems

When using latex reclaimed rubber to produce highly wear-resistant rubber products, the use of softeners will reduce the wear resistance of the rubber, and the use of aromatic oil softening has less effect on the wear resistance of the rubber. Appropriate addition of antioxidants can improve the heat resistance and fatigue resistance of the rubber compound while improving the abrasion resistance of the latex reclaimed rubber, such as antioxidant 4010NA, antioxidant RD, etc. When carbon black is used for reinforcement, adding a small amount of modifier containing nitro compounds to the formula can increase the dispersion of carbon black, thereby improving the abrasion resistance of the latex reclaimed rubber.

When using latex reclaimed rubber to produce high abrasion-resistant rubber products, the use of modified fillers treated with silane coupling agent or rubber-plastic blending can also improve the wear resistance of latex reclaimed rubber. There is a chance that the editor will continue to cooperate with You explore.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits