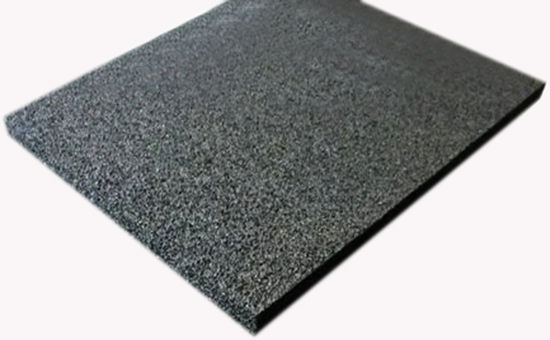

Rubber foamed sheet has the characteristics of light texture, good elasticity, bending resistance, etc. Natural rubber, styrene butadiene rubber, ethylene propylene rubber and other raw rubbers can be used to produce foamed sheet in different applications, and the effects of shock absorption, sound insulation and heat insulation are remarkable when used. The recycled tire rubber is processed from waste tire rubber powder, which has the characteristics of wide source of raw materials and low product price, and can be used to prepare foam sheets; Reasonable design of the formula of recycled rubber foam board and strict control of the production process conditions can reduce more costs on the premise of ensuring the use performance of the foam board.

1. Reference formula for foam board production of recycled tire rubber

100 portions of recycled rubber, 1.5 portions of zinc oxide, 1.5 portions of stearic acid, 0.75 portions of paraffin wax, 1.5 portions of polyethylene glycol, 0.75 portions of antioxidant, 7.5 portions of foaming agent ADC, 2 portions of low-temperature foaming agent ACP-W, 1.5 portions of sulfur, 1.5 portions of accelerator D, 1.5 portions of accelerator M, and 1.5 portions of accelerator BZ; Total: 121.5 copies.

2. Key points of foam board production of tire recycled rubber

(1) Feeding time of mixing mixture

It is suggested that the mixing process for preparing foam board from recycled tire rubber should be carried out in an internal mixer. When the temperature of the internal mixer is 70-90 ℃, paraffin, stearic acid and polyethylene glycol should be added in turn for pressurized mixing to make the master batch rubber. Regenerated rubber 2ELYY1026 master rubber can be added to the internal mixer for pressure mixing for 5-10 minutes, and then added with foaming agent ADC for mixing for 2-5 minutes, followed by sulfur powder, zinc oxide, accelerator, anti-aging agent RD and foaming agent ACP-W. After pressure mixing for 2-5 minutes, the material is discharged.

(2) Selection of raw materials for foam board production from recycled tire rubber

When using recycled tire rubber as the main raw material to produce foam board, the recycled tire rubber can be used alone or combined with a small amount of natural rubber, styrene butadiene rubber, cis-1,4-polybutadiene rubber or chloroprene rubber to further improve the comprehensive performance of the foam board. When the recycled tire rubber/raw rubber is used to produce foam board, it is recommended to fully plastic the raw rubber and then mix it with the recycled rubber. The selection of ultra-fine recycled tire rubber and fine recycled tire rubber with high fineness and no impurities can ensure the smooth foaming of the rubber; When the foamed board has requirements for environmental protection performance, it is recommended to use environment-friendly recycled tire rubber.

The main components of recycled tire rubber are natural rubber, general synthetic rubber and carbon black. The production of rubber foam sheets can not only ensure product quality, but also significantly reduce the cost of raw materials. When necessary, the recycled tire rubber can be used with the raw rubber. Later, Xiaobian will continue to share with you the parameter settings and precautions of each production process for the production of low-cost foam board from recycled tire rubber.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits