Statistics show that it is expected that the amount of waste tires produced in my country will reach 20 million tons in 2020, which is a huge number! At present, the main method of recycling waste tires in my country is to process recycled rubber, so expanding the application range of tire recycled rubber in the rubber products industry is of great significance to solve the problem of waste tire pollution. When using natural rubber to produce foamed rubber products, the rational use of tire reclaimed rubber can not only ensure the quality of foamed rubber products, but also significantly reduce the cost of raw materials.

1. General reference formula for the production of foamed rubber products with a high proportion of tire reclaimed rubber

100 parts of natural rubber, 500 parts of tire reclaimed rubber, 2.5 parts of zinc oxide, 14 parts of stearic acid, 4.2 parts of antioxidant D, 110 parts of light calcium, 60 parts of clay, 10 parts of spindle oil, 55 parts of black grease, foam 5 parts of agent H, 10 parts of baking soda, 2.8 parts of accelerator D, 4.8 parts of accelerator DM, 1.6 parts of accelerator M, and 6.7 parts of sulfur; total: 886.6 parts.

2. Natural rubber/recycled rubber combined use to produce foam rubber product formula design skills

When using recycled tire rubber in the formulation of foamed rubber products with natural rubber as the main raw material to reduce the cost of raw materials, rubber product manufacturers need to determine the amount of tire recycled rubber 2LLYY624 according to the actual needs, and adjust the types of compounding agents in the formulation system. With dosage. In general, when a large amount of tire reclaimed rubber is used in the formulation, the amount of light calcium and clay can be appropriately reduced; the compounding agents in the vulcanization system and softening system should be adjusted accordingly.

It should be noted that when adjusting the vulcanization system according to the amount of reclaimed rubber, the foaming system must be adjusted in advance, and after determining the foaming rate, the vulcanization system compounding agent should be adjusted to match the foaming speed.

3. Foam rubber products to reduce costs, how to choose the right tire recycled rubber

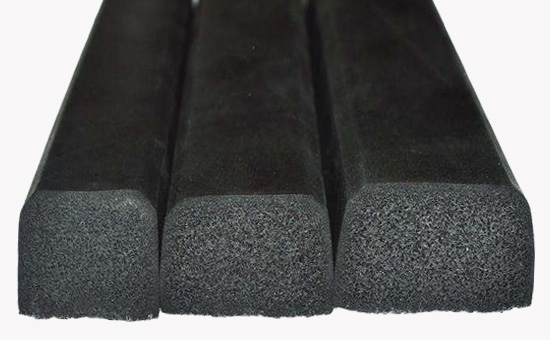

By using tire reclaimed rubber and a small amount of natural rubber in combination, various types of foamed rubber products such as foamed rubber sheets, foamed rubber strips, foamed hoses, and foamed soles can be prepared. Under normal circumstances, the use of tire reclaimed rubber to reduce the production cost of indoor foam rubber products such as indoor foam rubber sheet requires the use of environmentally friendly, odorless tire reclaimed rubber; when using tire reclaimed rubber/natural rubber and rubber to produce extruded hoses and rubber strips , High-fineness tire reclaimed rubber should be selected to ensure smooth extrusion of extruded products; foam products with high wear resistance requirements are best selected tire tread reclaimed rubber.

When a large amount of tire reclaimed rubber is used in foamed rubber products to reduce the cost of raw materials, rubber product manufacturers must choose tire reclaimed rubber with appropriate indicators, rationally adjust the formula of foamed rubber products containing tire reclaimed rubber, and further reduce it on the premise of ensuring quality Raw material costs.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits