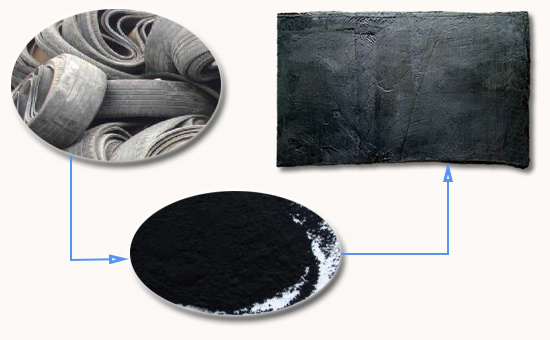

Hongyun Ultrafine Tire Recycled Rubber is a reclaimed rubber made from fine 80-point tire rubber powder. Compared with ordinary tire reclaimed rubber, the surface of the rubber products produced is smooth and bright, which can only be used when the tire reclaimed rubber is changed. The fate of producing molded rubber products. The production of Ultrafine Tire Reclaimed Rubber is a complex and meticulous process.

Hongyun Superfine Tire Recycling Products are going through the following processes: recycling of used tires → sorting and sorting → cutting gel → washing → crushing → screening → magnetic separation → air separation → weighing (weighing powder and regenerant) → mixing and mixing oil → Desulphurization → Flushing (Water Washing) → Pressurized Water Drying (Water and Oil Process) → Kneading → Filtering → Refining → Reclaimed Rubber Finished Products. Among them, filtration separation in the production process of ultra-fine reclaimed rubber has a great influence on product quality and service performance.

The so-called separation of filtration is an important section for controlling the quality of ultra-fine reclaimed rubber products. In this section, the crushed waste tire rubber powder needs to be placed in a 0.18 mm diameter screen to pass through the screen, and the fineness is greater than 80 mesh. The impurities in the rubber powder and the rubber powder are separated. The magnet is also used in this step. Because the waste steel wire will contain iron chips, it is necessary to classify the iron chips in the waste tire rubber powder to ensure that it will enter the next desulfurization process. The fineness of the tire rubber powder reaches 80 meshes, thus ensuring the ultra-fine in the ultra-fine tire reclaimed rubber.

In addition, the main processes of ultra-fine reclaimed rubber production are crushing, desulfurization and refining the bottom sheet, in which the crushing is to cut, clean, and crush the waste tires after sorting; the desulfurization process directly affects the quality of reclaimed rubber, especially It is important to refine the film by sending the desulfurized rubber powder after drying to the kneader, kneading it repeatedly and returning it to the refining machine, mixing it evenly, and then putting it in the refiner to make it thinner. Hongyun superfine tire reclaimed rubber production process has a professional technical staff supervision throughout the production of ultra-fine reclaimed rubber after a rigorous sampling inspection, after passing the test after a period of time before the sale was sold, rubber products manufacturers can rest assured that use.

Hebei Hongyun Reclaimed Rubber Factory produces ultra-fine reclaimed rubber products with high fineness, high strength, and small specific gravity. The surface of the produced rubber products is more black and bright, suitable for all kinds of hoses, sealing strips, inner tubes, wire and cable jackets, etc. The production of rubber products significantly reduces the cost of raw materials.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits