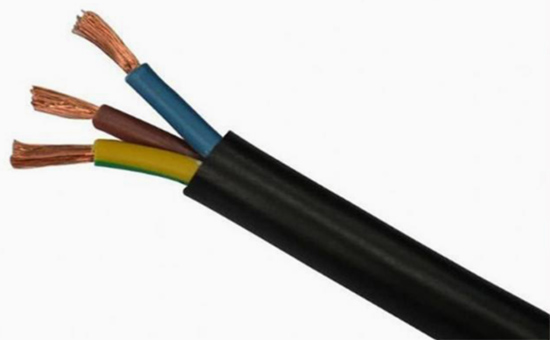

The so-called soft wire is naturally speaking with respect to the hard wire. It is a wire with a softer wire that is entangled with many fine wires. It has better pressure resistance, load capacity and higher cost performance, so it is very popular in the market. The rubber outer skin of the flexible wire mostly uses natural rubber, but the price of natural rubber is high and prone to fluctuations. Therefore, many rubber product manufacturers have begun to use an appropriate amount of reclaimed rubber in the soft wire formulation using natural rubber as the main raw material to reduce the production cost.

15 parts of natural rubber, 10 parts of tire reclaimed rubber, 10 parts of rubber reclaimed rubber, 15 parts of hard asphalt, 1 part of zinc oxide, 10 parts of clay, 40 parts of chalk, 1 part of sulfur, 0.6 parts of accelerator; total: 102.6 parts .

Control cost

Recycled rubber can be divided into latex reclaimed rubber, tire reclaimed rubber, rubber reclaimed rubber, nitrile reclaimed rubber, butyl reclaimed rubber and EPDM reclaimed rubber according to the source of raw materials. Among them, rubber reclaimed rubber has the lowest price and tire regeneration. The maximum amount of glue is slightly higher than the rubber reclaimed rubber. In the above formula, the tire reclaimed rubber, the rubber reclaimed rubber and the natural rubber can be used together to produce a soft wire sheath to control the rubber cost at a very low level.

2. Optimize the formula

The hard asphalt is black solid block and has a high softening point. It can be used as a softener in the formulation. However, since the hard asphalt contains non-environmental carcinogens such as polycyclic aromatic hydrocarbons and benzopyrene, it should be hard in the formulation. The asphalt is replaced by an environmentally-friendly rubber softener to improve the processing performance of the rubber compound; the chalk is a loose calcium deposit formed by microorganisms, which is basically consistent with the action of calcium carbonate in the formulation, which can increase the volume of the product and reduce the production cost. To improve the tensile strength, tear strength and wear resistance of soft wires, in order to further improve the physical properties of soft wires, rubber manufacturers can appropriately reduce the amount of chalk and increase the amount of white carbon black.

3. Which reclaimed rubber can be used in soft wires?

The use of low-cost rubber reclaimed rubber, tire reclaimed rubber, hard asphalt, and a large amount of inorganic filler in the soft wire formula are all possible to reduce the cost of the soft wire sheath formulation, but in practical applications, low cost The soft wire formula may not be able to meet people's growing environmental protection needs. Rubber product manufacturers can also use latex reclaimed rubber and environmentally-friendly tire reclaimed rubber to improve the physical and mechanical properties of soft wires according to the actual specifications of soft wires, manufacturer scale, and cost budget.

Note: Natural rubber, latex reclaimed rubber, tire reclaimed rubber and other rubbers have good electrical insulation, but the addition of sulfur accelerator during vulcanization will introduce polar factors, thus reducing the electrical insulation of the soft wire sheath, so it contains reclaimed rubber. Special attention should be paid to the design of vulcanization systems for flexible cords.

Exclusive original article [commercial authorization] reprint, excerpt and excerpt in any form are prohibited without written authorization. Focus on Hongyun rubber: learn the process formula and raw material technology of producing rubber products from recycled rubber to help you reduce costs and increase profits